COMPANY INSIGHT

Sponsored by REPI

Reduce, reuse, recycle... refit!

That plastics are blamed for polluting is a sad fact, but probably exactly the negative image wrongly addressed to them is what challenges plastics stakeholder to firmly prove the contrary. REPI is among them, being a supplier of colours and additives to the plastic packaging industry for many years, developing customs-made solutions to meet the evolving needs of their converters and Brand Owners.

The continuous research and development of solutions has been increasingly driven, over the years, by the willingness to actively contribute in creating packaging that is environmentally friendly and that highlights the unparalleled properties of plastics, especially for single-use packaging. It is worth retracing once again some of the reasons why plastics are so successful in packaging: they preserve food from degradation, they make their transport all over the world easy and safe, a plastic packaging is lighter than any other packaging and therefore consumers can practically carry their on-the-go snacks and drinks while commuting to job.

Finally, but not less crucial, plastic packaging helps reduce CO2 emissions, especially when it involves recycling. A recent report of Plastics Europe shows that an increase in the recycling rate of 5mt of plastic packaging would make CO2 emissions falling by 7mt, corresponding to 2,4 million cars less on streets.

A PET bottle made of 50% R-pet has a lower environmental impact than a glass bottle (be it single use and reusable) or a tin can. Environmental impact means: contribution to climate change and smog as well as water consumption. The single use glass bottle is the least environmental unit, even behind aluminium tin which is almost always the runner-up to plastic packaging.

Crucial in this context is recycling, as we very good know. Plastics are too valuable resources to be simply thrown away, they need to be reused and recycled.

The 3-R statements adopted by many plastics stakeholders very good summarize in which directions we need to move: reduce the quantity of plastic we put on the market (light weighting is a good example), reuse it whenever feasible and recycle.

REFIT: acting responsibly towards sustainability

REPI has created its own 4th “R” besides reduce, reuse, recycle: REFIT.

REFIT is the new brand representing the company’s approach towards a sustainable growth and environmental care. Before coming to products, REFIT involves internal processes, from the choice of raw materials, to the tuning of low energy production cycles, to the choice of renewable energy sources for its facilities and, needless to say, separate waste collection.

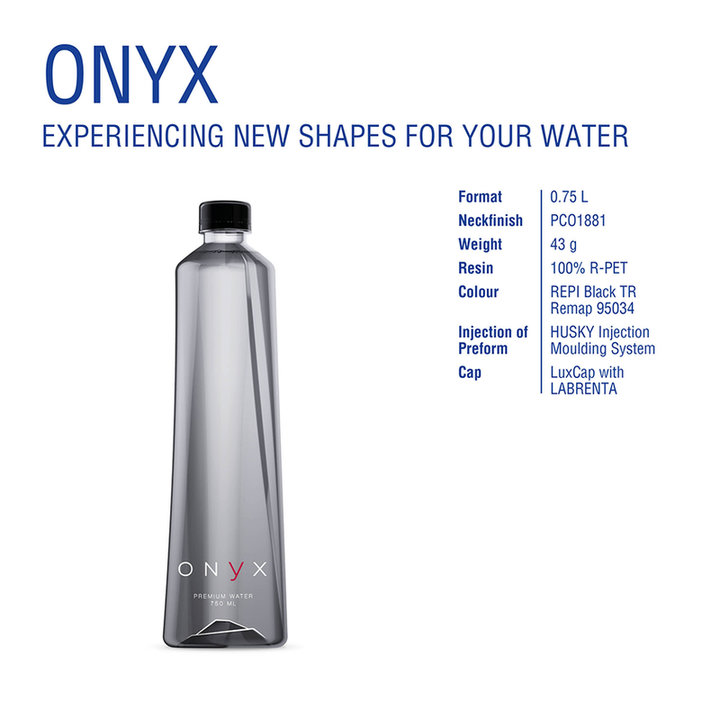

100% r-PET and REPI Fumé Black for a premium water dedicated to the Ho.re.ca.

Now coming to products, REPI has been specialising in additives and colours for recycling for may years and is today able to offer a broad-spectrum support in the form of aesthetics enhancers and mechanical boosters: Anti Yellow (AY) additives and IV-enhancers.

The colour of r-PET varies a lot from supplier to supplier (and even from one batch to the next) and depending on the ratio of virgin and recycled PET used, the result can be anything from grey or pale yellow, to blue or greenish. The more recycled content the bottle has, the darker the end colour will appear.

Mechanical challenges when using r-PET include a drop in the Intrinsic Viscosity (IV). This happens because the PET, after several production cycles, due to degradation processes, shows a reduction in the molecular weight: its chains are shorter and mechanically the final product is weaker.

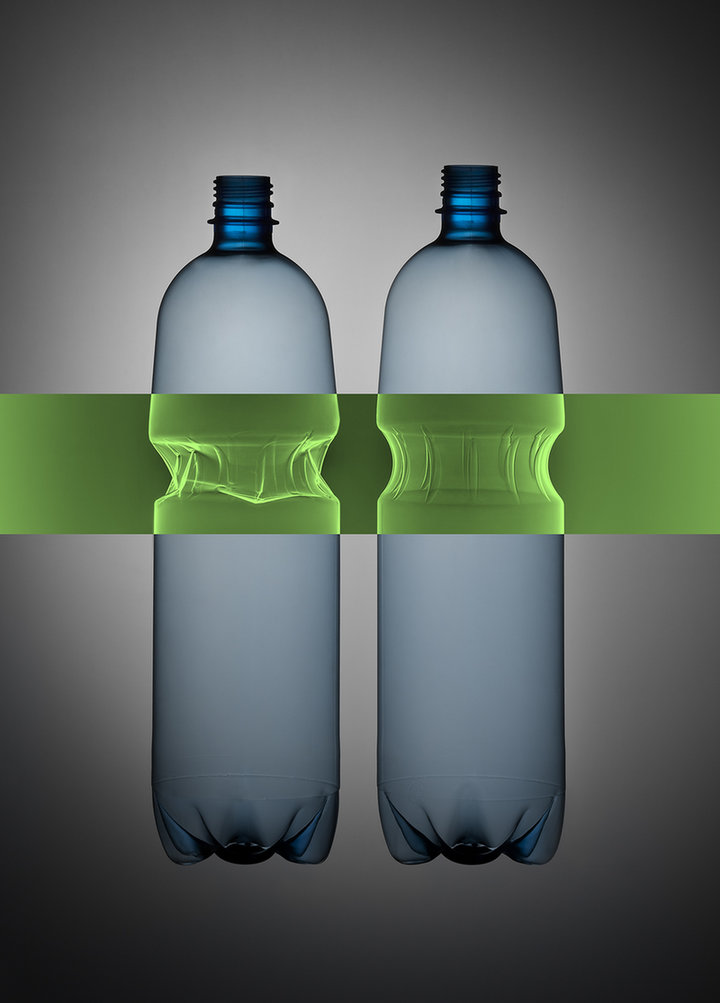

One single shade starting from two different r-PET

REPI’s prototyping research and development laboratories mould preforms and bottles and experiment with colours and additives using r-PET pellets and flakes mixed in different percentages.

The AY range comprises different liquid additives able to balance the appearance of variations in material and makes it possible to regain brightness, as well as to correct a greenish or greyish tone.

REPI’s IV Enhancer combine shorter molecular chain to longer ones, thus increasing the IV of the material.

REPI’s IV enhancer additive boosts the mechanical performance of an r-PET bottle by increasing the IV level from 0,05dl/g to over 0,10dl/g

Besides additives, colours can be of great help!

The use of r-PET presents a challenge to brand owners, who are not ready to sacrifice the aesthetics of their packaging and their brand recognition. When a very dark r-PET is used, an Anti-Yellow additive may not be enough. For this reason, REPI has developed the Fumé colour range that can give the packaging a premium and elegant look, masking the effect caused by r-PET on the colour. The Fumé colour range is used at very low dosages (as low as 0,05%) so it does not impact the recycling stream because it is detected as a transparent light colour. The range goes from light amber to light blues, greys, aquamarine shades and even antique rose.

“Moving towards a circular economy is not simple, but solutions are already in place to help as much as possible to find how to be sustainable from a branding and aesthetic point of view as well as from a technical perspective”, says REPI. ”Colourants and dedicated additives are available to make r-PET look and work even better. Take advantage of this opportunity, because after all… how would the world look without colour?”

Contact Information

Lucia Buffoni - Marketing Manager REPI S.p.A.

Web: www.repi.com

LinkedIN: Repi S.p.A.: www.linkedin.com