Emulate3D

Dynamic Digital Twin Technology

Emulate3D technology is designed to help packaging line integrators and machine builders reduce commissioning time and costs. Take the logical verification of your control systems off the project’s critical path, and carry it out offline, before you go onsite. Simplify and shorten onsite validation by turning up with fully tested operational logic, and reduce the risk associated with your automation investments.

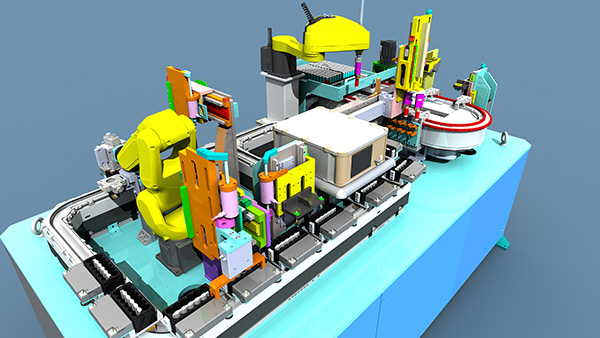

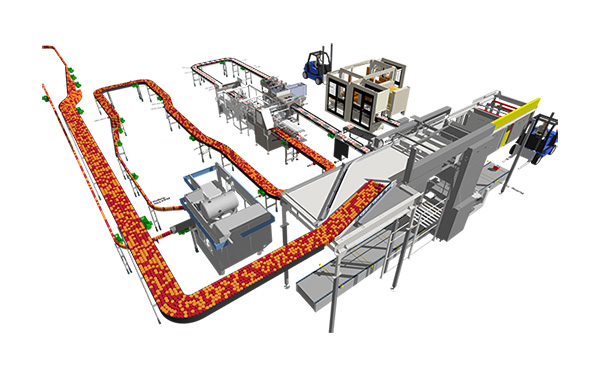

Create a Dynamic Digital Twin of your System

Emulate3D enables you to bring together the 3D CAD of your machine or system with the actual control system, before the real system has been assembled onsite. By creating a Dynamic Digital Twin of the system with full sequential operation driven by the actual control system and activated by the realistic introduction of loads or products into the system, users can run and test the system using the actual HMIs which will be connected to the real system.

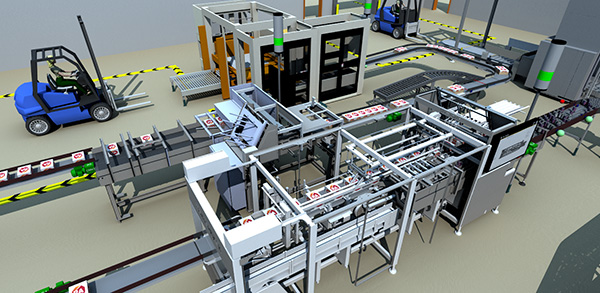

Test Your System Fully via its Dynamic Digital Twin

The primary purpose of an Emulate3D model is to verify the operation of the control system under all operating conditions, including recovery following incidents. Errors can be safely and cost-effectively detected and remedied without causing physical damage to products or equipment. Operators can be fully trained under realistic conditions and without disruption to production or maintenance procedures. By creating virtual representations of your machines and systems you’ll also significantly reduce prototyping time and costs.

To learn more, contact Tyler Phillips +1 801-923-3316 and see www.demo3d.com.

See Emulate3D for Machine Builders on YouTube.