Feature

Why isn’t Europe investing more in recycling plastic?

Despite the huge environmental cost of waste plastic, even in Europe recycling rates remain incredibly low. Jon Whiteaker reports.

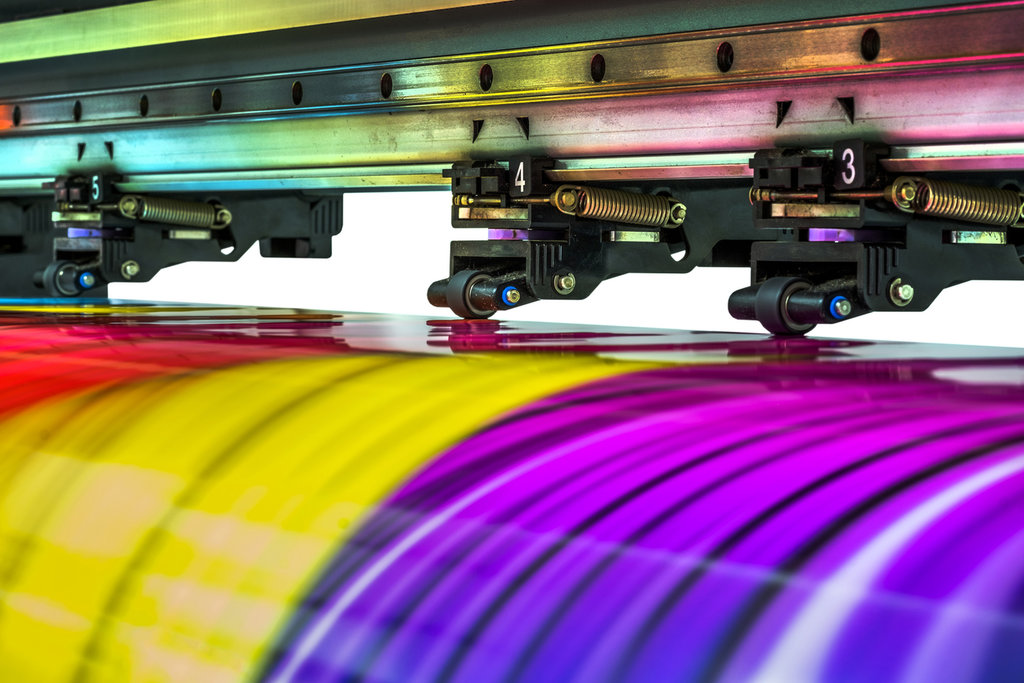

The recycling of plastic brings mixed results, which means investments are often low. Credit: Shutterstock

The invention of plastic manufacturing changed the world. Look around you now and wherever you are, you are likely to be surrounded by products and structures containing plastic.

However, we need to produce less plastic waste to preserve the environment, so why don’t we recycle more? Citizens, particularly in richer nations, have been sorting their plastic waste for recycling for decades now, yet the rates of plastic recycling remain minimal.

Low rates of plastics recycling

According to the OECD, just 9% of plastic waste globally was recycled in 2019, while 49% ended up in landfill, 22% was uncollected and mismanaged, and 19% was incinerated. The world is producing twice the amount of plastic waste that it was two decades ago.

Plastic waste is not purely a developing world problem either. OECD countries in Europe recycled just 14% of their plastic waste in 2019. The US recycled just 4%.

The EU is introducing measures to try and address this growing problem, but even here the outlook is bleak. Technological, regulatory and financial constraints mean European plastic recycling capacity is not growing at anywhere near the rate of plastic production.

The OECD projects that by 2060, 50% of plastic waste will still be going to landfills and the volume of plastics incinerated will still be greater than the volume of waste recycled.

Peter Börkey, principal administrator at the OECD Environment Directorate, says that we are on a trajectory to achieving better results with plastic recycling, but that will take a long time. “If the public was more aware that plastic sorting is not leading to great outcomes, it might discourage them”, he says. “It is better to communicate the end goal.”

And then the second question was how do you then start to tackle it?

The problem with plastics recycling

The main form of plastics recycling is known as mechanical recycling. This involves sorting and breaking down plastics through mechanical processes. It does not change plastic materials’ chemical structure, so limits the ability for the waste to be reused for new purposes.

Only certain types of plastic are suitable for recycling, and while single-use plastics are coming under increased regulatory control, even when plastic is recycled it is of low quality. Plastics collected kerbside are often contaminated, making them unsafe for reuse for many applications, particularly for any food-related purposes.

Chemical recycling is touted as a magic bullet. This would breakdown plastics into new chemicals that could then be used in the same way as “virgin plastics”. However, the various technologies attempting this process remain unproven, with questions about whether chemical recycling can ever be delivered at commercial scale. The process also releases greenhouse gases, attracting opposition from environmental groups.

Because of the poor quality of plastics recycling, much of the waste collected in rich countries is exported to other, typically poorer, countries or incinerated for power, a process that creates air pollution.

Mines in Bayan Obo in Inner Mongolia, China, extract one the largest deposits of rare earth metals found in the world. Credit: Bert van Dijk/Getty images

The business case for plastic recycling

Plastics recycling is inefficient, but it is also poorly invested in. Governments in Europe are attempting to use incentives and regulations to try and increase the volume of plastics recycled.

The UK government produced a report on plastics recycling in late 2022. The report stated that “during the inquiry, we repeatedly heard the UK has insufficient recycling capacity”.

Evidence submitted for the report suggested there was £500m ($605.18m) to £1bn of private capital ready to be mobilised, but barriers to investment include: a lack of stable and sustainable income for recycling companies; the fact that domestic processing is more expensive than exporting waste; and uncertainty about where to invest.

Viridor, a waste recycling company that operates in the UK, estimates that the country will need around 24 new plastic sorting facilities and between 18 and 22 reprocessing facilities by 2035 – not inclusive of capacity for hard-to-recycle plastics.

In a report the company published in 2022, it highlighted major barriers to further investment in the sector. Volatility of revenues, with no guaranteed ‘gate fees’, means investors don’t view these facilities as an infrastructure asset. Among its proposals to government were raising the barriers to entry by increasing standard requirements and introducing policy that will guarantee higher rates of waste for collection.

The UK introduced the Plastic Packaging Tax in April 2022 to add additional costs to using virgin plastic. Some have questioned, however, whether the £200 per metric tonne (t) charge is high enough to act as a push on industry, particularly as some industries say that the 30% recycled content target will be uneconomical to achieve for their products, while others will meet that easily without changing how they do business.

Germany passed legislation in late 2022 that will require makers of products containing single-use plastic to pay into a central fund managed by the government that will pay for litter collection. It is expected to raise €450m ($482.01m) in its first year after adoption in 2025.

This form of punitive regulation on plastic manufacturers seeks to make single-use plastics uneconomical as a manufacturing material. Others want to see action on the export of the problem to poorer countries. In January 2023, the European Parliament approved a law introducing stricter control on waste shipments from the EU.

Börkey of the OECD believes it is too early to know how effective these legislative attempts will be. “It is an experimental policy area where we cannot draw on decades of experience to know what will work, and what won’t,” he says.

The impact of legal challenges

Crude oil and natural gas are the feedstocks used to produce plastics, and oil and gas companies are under increasing pressure to address the pollution caused by the products made in their petrochemical facilities.

These companies have been the biggest proponent of chemical recycling, announcing various initiatives in recent years. In its sustainability report published in 2021, for example, Shell said it was investing in facilities in the Netherlands to convert more than 30,000t a year of plastic waste into pyrolysis oil, which it would use as a replacement feedstock.

Environmental groups have accused oil and gas companies of greenwashing the problem with plastics, offering unproven technological solutions when they should just be made to reduce the amount of plastic produced.

A test case that could have a big impact on plastics producers is a legal challenge filed by a group of environmental non-governmental organisations against Danone, the French multinational that makes products such as bottled water and yogurt.

The lawsuit accuses the company of not doing enough to limit the environmental impact of the plastic waste created through the consumption of its products. A host of plastics-based legal challenges are expected to follow the Danone case, all trying to force companies to use less plastic in their packaging.

Although rich countries have been recycling for decades, it is doing little to prevent the environmental damage caused by plastics. It may be that the only realistic way of doing that is to dramatically reduce how much plastic we use.