COMPANY INSIGHT

Established

in 1996 with headquarters now in Arnhem, the Netherlands, MPS Systems has transformed into a successful player in the printing sector with offices in the UK, Germany, the US and Malaysia. Today, its products are exported to markets across all continents through a network of offices and agents.

MPS Systems began as a supplier of flexo printing equipment for label printers, and the first to introduce servo driven printing technology into this market. Over the years, their product gamut expanded with larger printing presses (mid-web) for flexible packaging printing and an offset press.

Their latest introduction is a hybrid combination of flexo technology with a completely integrated digital ink jet unit, combining the best of both flexo and digital printing technology.

Operator Focused, Results Driven

MPS is known for its high quality, robust presses. But what divides MPS from their competitors? By designing presses that can be easily used by operators, regardless of their skill level. If the operator can assure good print quality and easily knows how to run the press, a stable end result is guaranteed.

MPS is dedicated from design right through to installation and after-sales support. It also offers an extensive customer care package such as project management, remote diagnostic control, preventive maintenance programmes and a help desk for quick problem-solving.

Beyond the Machine

Offering more than just printing equipment, the cornerstone of MPS is described as ‘Beyond the Machine’.

Atze Bosma, CEO of MPS explains: “MPS goes beyond the machine. We strive for maximum press performance, for your maximum business results. We do this through innovations in Connectivity and Productivity, by sharing our knowledge of machine operation and Applications, and by offering best-in-class Service.”

Maximizing productivity through data

What’s sets MPS apart in the industry is their ‘talk to me’ connectivity technology, a platform now included with every new MPS printing press.

Talk to me connects printing machines and workflow with Management Information Systems (MIS) for real-time data exchange and control. With this data intelligence from MPS presses, you can determine where your bottlenecks are.

Better performance - in areas of job changeovers, services, operator training and measuring results to create process and workflow improvements for the printing machine and more efficient production - is made possible.

Meet the MPS product gamut

The MPS product gamut consists of five different press models for label and flexible packaging printers.

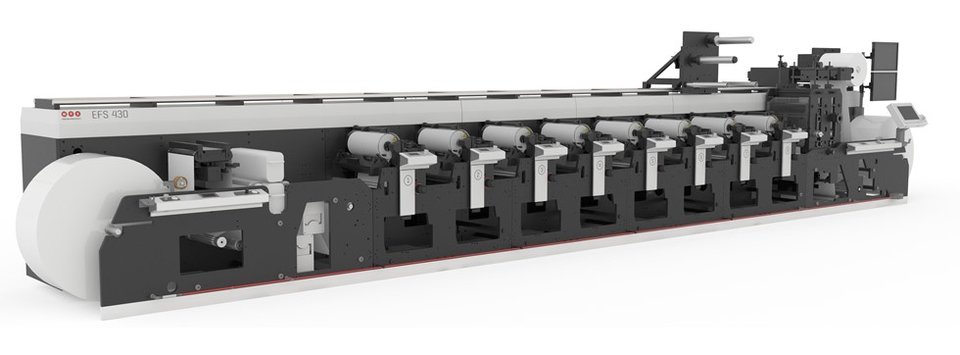

EFS: multi-substrate flexo press

The EFS is a high-quality, highly automated multi-substrate flexo press, especially designed for label production and flexible packaging printing on various substrates. The easy-to-use and highly reliable EFS press can also produce multi-layer labels, with unique solutions such as the cross-over unit and multi-web application.

EFS: The Automated Multi-substrate Press

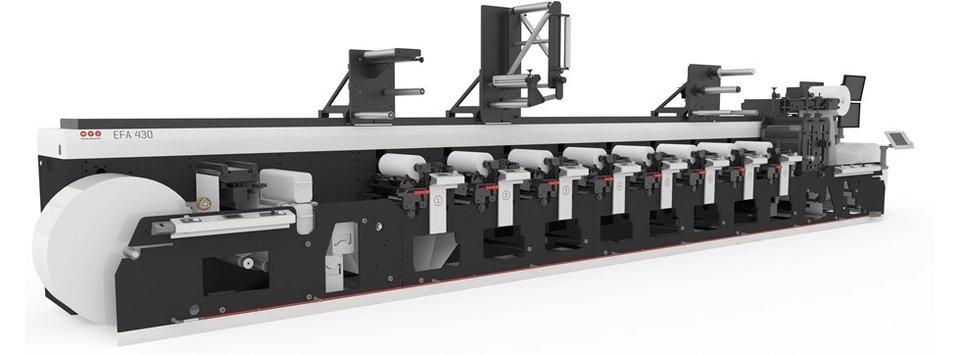

EFA: fully automated flexo press

The EFA model is a top-quality, fully automated multi-substrate flexo press, geared up for label production and flexible packaging printing on various substrates. Servo-controlled pressure settings for the print sleeve at each print station are provided. For the next level of automation, the EFA+ package can be added for full servo-driven automation of all print pressure settings.

Providing the ultimate in flexibility and automation, the EFA is the most future-proof press available.

EFA: The Fully Automated Multi-substrate Press

EF SYMJET: Best of both flexo and digital printing

The EF SYMJET press is a hybrid printing solution, combining conventional flexo with digital inkjet technology from the Domino digital N610i inkjet printer.

Available in 340 mm/ 13” and 430 mm / 17” widths, the EF SYMJET press can be equipped with multiple flexo units, lamination and embellishing units, die-cutting and many more converting options.

EF SYMJET: The Hybrid Printing Solution

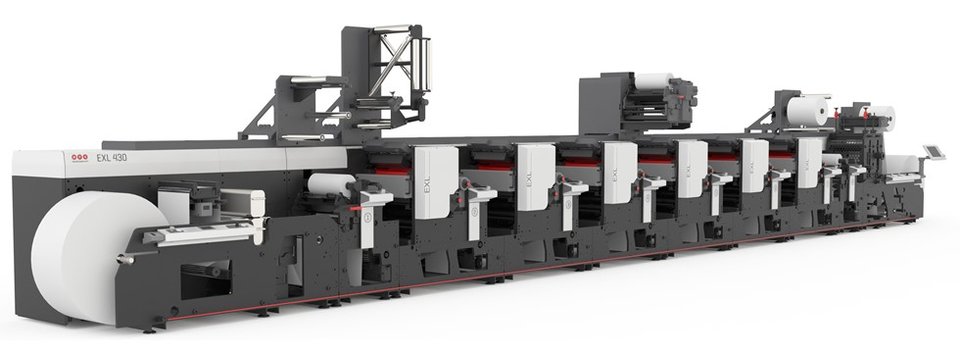

EXL-Packaging: Mid web packaging press

Next up, the MPS EXL-Packaging press delivers wider and faster flexo printing without limits, meaning flexible packaging printing and converting with the use of an inline press is more economical than ever.

With the EXL-Packaging press, extremely fast change-over times and remarkably short set-up waste guarantee optimal and productive printing and converting.

EXL-PACKAGING: The Mid Web Packaging Press

EXL-Offset: for offset sleeve combination printing

The revolutionary EXL-offset press, with offset sleeve combination printing, is the most versatile offset press available in the market. It offers variable sleeves for different repeat lengths, for both plates and blankets, and is easy to operate.

EXL-OFFSET: The Offset Combination Press

Technology & Expertise Centre

At the company’s headquarters in Arnhem, the Netherlands, and at its US facility in Philadelphia, MPS has established a Technology & Expertise Centre, an environment where press improvements and new technology developments happen in response to market trends.

The centres also offer training and technology tests for printing press operators and engineers to ensure they are fully conversant with the MPS products they will be working with.

Schedule a personal appointment to visit the Technology & Expertise Centre in Arnhem or in Philadelphia to learn more about MPS and their solutions for label and flexible packaging printers.

Cover image: Dassault Systèmes