company insight

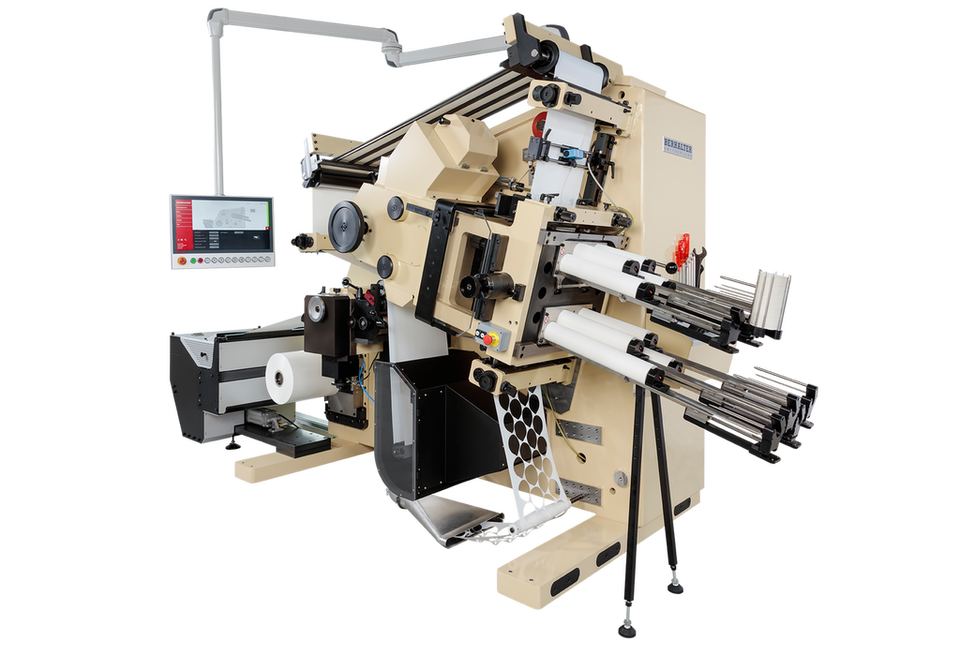

Berhalter's

die-cutting machines have an average lifetime of 40 years, and take care to treat environmental resources with a responsible attitude. The first die-cutting machine built by the company is still running. And, if spare parts or maintenance are needed, Berhalter will supply them. Contrary to popular belief – that too long a life of a product kills business – Berhalter does everything to ensure that its die-cutting machines can be passed on from generation to generation. A product that lasts for a long time leads to a long-time business relationship. But to Berhalter, the most important thing is that its machines allow its customers to respond to the market requirements and the needs of their clients, even after half a century. Whenever you need to respond flexibly and rapidly to demands, with Berhalter you are able to adjust to the dynamic market.

Retrofitting and upgrading

Once you come to the conclusion that your Berhalter die-cutting press needs to be updated or replaced, the company is more than happy to take it back for retrofitting. It also repurchases machines and sells them in markets with low purchasing power, or sells to converting or packaging companies that do not have very large quantities to punch. Berhalter makes sure that the retrofit machines meet requirements, such as CE (European Conformity), and are equipped with the latest technological standards. It goes without saying that its tools can also be modified at any time during a project. They can not only be serviced and improved, but also modified for additional functions. Put simply, Berhalter’s tools are incredibly versatile.

Courtesy of Llanllyr SOURCE

Image of

Less electricity consumption than a hairdryer

Due to a recuperation system, Berhalter has managed to reduce the electrical consumption of its die-cutting machines significantly. As well as reducing energy consumption directly, recuperation also brings an indirect reduction as the energy is recuperated and less heat is produced. Berhalter die-cutting machines are the only one in the market using this technology – an example of just one of many technologies showing the company’s visionary thinking and pioneering role in the die-cutting industry.

Keep an eye on punching waste

When Berhalter designs a punching tool it always keeps an eye on waste. Cavities are arranged so material can be saved without risking the stability of the tool. Performance and output will also not be neglected, as, of course, the durability of the tool is a key factor of sustainability. Recycling and reusing the waste of aluminium or polyester foils has been standard for decades, and the need to act consciously is no longer only a trend.

Sharing expertise

These days, it is not enough to only sell products or to be just a service provider. Berhalter believes that ensuring that its customers can meet their needs is more important than ever before. It isn’t afraid to share its experience and expertise, which the company has gained over many years, as it is genuinely interested in its customers success. Their success, after all, is also Berhalter’s success. Although it sounds like an advertising phrase, in this case it is sincere.