Company Insight

Sponsored by MPS Systems

Connect to Grow with MPS

As a label or flexible packaging printer, you face a rapidly changing market with increasing pressure on price and higher demands on quality and flexibility. At the same time, you must cope with different printing techniques, more changeovers and a growing shortage of experienced operators.

Whether you are using a flexo, offset, or a digital hybrid printing press, you strive for maximum performance and maximum return on investment. This requires expertise, use of unbiased data and in-depth advice to improve quality, performance and Total Cost of Ownership of the actual printing press.

Pioneers in servo-driven flexo printing

Established in 1996 with headquarters in Arnhem, the Netherlands, MPS has transformed into a successful player in the printing sector with offices in the UK, Germany, the US and Malaysia. Its products are exported to markets across all continents through a network of offices and agents.

MPS began as a supplier of flexo printing equipment for label printers, and the first to introduce servo-driven printing technology into the market. Over the years, the MPS product gamut has expanded with highly automated flexo, hybrid, and offset printing presses with intelligent connectivity for the label converting and flexible packaging industry worldwide.

Connect to grow

MPS’ mission is to enable customers to unleash the full potential from their presses. It is about running robust, reliable, highly qualified and highly automated printing presses ready for 24 x 7 operations.

MPS enables you to achieve the best performance and maximum return from your MPS machine. Together, they look ‘beyond the machine’ through intensive cooperation, focusing on their customers’ results by addressing all aspects involving the printing press.

24-7 valuable insights with MPSConnect

In the label and flexible packaging industry, printers rarely collect unbiased, real-time data from the actual printing press. Operators fill in the events and functions. As a result, important criteria such as accurate changeover time, web tension of the infeed and outfeed, exact set up times and waste are not clearly known. This information is valuable because many machines run much less than what they can.

With MPSConnect, MPS dives into your printing press and sees exactly what’s happening. Hundreds of sensors built into these intelligent presses collect and store data from hundreds of events per second.

These valuable insights are available 24x7 in the Performance Dashboard on your mobile, computer, press, wherever you are. Based on these online, fact-based insights you can optimize your present press performance and decrease waste.

Focused support from a team of MPS experts can help you shorten job production time and minimize material waste. Based on data insights via MPSConnect, MPS supports you in defining performance goals and actions to achieve performance improvements - and thus increase competitive advantages and maximize profits.

You gain with MPSConnect:

- Real-time performance insights of your machines for relevant KPI’s

- Information about maintenance and service

- Benchmark information against industry leaders

- Identified bottlenecks, errors and inefficiencies in the operator process

Recommendations for performance optimization and suggested tools from a team of experts.

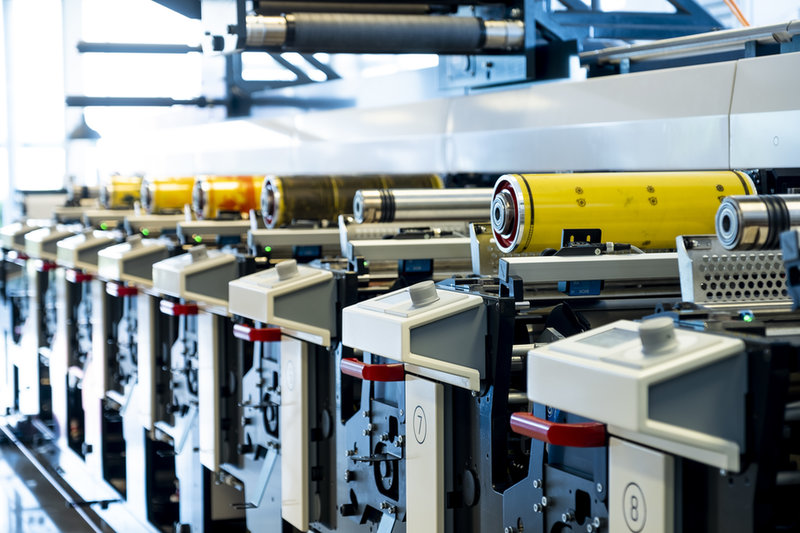

MPS EFA press

Raise the bar in print quality: The MPS product gamut

EF SYMJET

In web widths of 22’’ (558mm), 20’’(508mm), 17” (430 mm) or 13” (330 mm), the MPS EF SYMJET hybrid printing press provides a range of new print potential with the symbiotic combination of conventional and digital printing technologies.

The EF SYMJET is built with an integrated Domino digital N610i inkjet printer which can be combined and used integrated in-line or separately to work offline.

EFA

High-quality, fully automated multi-substrate flexo printing press that prints on various substrates. Each print station provides servo-controlled pressure settings. It’s a top-notch press choice for a connected future.

EFS

Highly automated flexo printing press for high quality printing on various substrates. It provides the ultimate in flexibility, enabling operators to maximize press performance thanks to its ease of operation and reliability.

EXL-Packaging

Wider flexo printing for narrow to mid-web printers and converters. The EXL-Packaging press provides inline capabilities that supports short to mid-size printing runs on a large variety of substrates.

EXL-Offset

With offset sleeve combination printing, the EXL-Offset provides variable sleeves for different repeat lengths for both plates and blankets, significantly reducing waste. Offering versatility in converting and drying options, a diverse range of packaging applications can be printed including flexible packaging, shrink sleeves, wrap-around labels, blisters & lidding.

For a wide range of embellishments, different printing and converting units can be integrated on all MPS presses such as screen, gravure, laminating, hot foil and cold foil units.

Grow your business with MPS

By connecting with MPS, you ensure the best in reliability and productivity from your printing press long into the future. With MPS performance programs, you’ll increase competitive advantages and maximize profits.

Main Image: The PW12C single point load cell