Company Insight

Sponsored by REPI

It is time to re-focus

New packaging solutions are among the key issues in a world that is confronted with huge amounts of plastic waste every day.

Mid-range One-Step Injection Stretch Blow Molding Machine – ASB-70DPH

F

or the plastic industry the year 2020 has been a major deadline for so many projects, pledges, activities at all levels. Goals were ambitious, but time was an ally. Already a couple of years back some goals started to be postponed to 2025, some even to 2030…because as we very good know…time flies and unplanned complexity is often entering the scene.

Enabling Customer to Innovate Faster

Die-cutting is a piece in the complete supply chain of a final product. But nor the less it decides significantly about success. What die-cutting solution you choose decides about appearance of the product, sustainability, quality as well as efficiency.

Over the last few years, BERHALTER has reacted continuously and highly flexible to increase market demands and has introduced a number of innovations to the market. Alongside its capacity for constant innovation, BERHALTER is synonymous with the production of efficient and customer-oriented die-cutting systems. We specialise in the manufacturing of user-friendly but high productive die-cutting machines.

From leading the world market to a new field

With no doubt such a complexity like the Covid-19 one could be imagined even remotely. So it happens that this year, that was meant to mark important acceleration of transition to an economy made of plastic alternatives have instead underscored that plastics are still the most reliable and affordable solution for personal protection. The pandemic is challenging everyone’s lifestyle, habits and daily life, even of those who are fighting for a reduction when not a ban of plastic. Many sustainability-conscious people may now find themselves with single-use plastic items, such as disposable wipes and sanitary protective devices, but also plastic bottles of hand sanitisers up to takeaway food containers and single serve drinks packaging.

It seems now that not only giving up disposable plastic is not feasible but on the contrary is the safest choice right now. If we look at the world consumption rates of last quarter, single use packaging is at a record high from north to south and this will last for a while, together with the demand of plastic disposable wipes, gloves, masks, etc.

In such a context the best think we can hope for is to this global black Swan occurrence as a renewed push to boost a circular economy of which of course plastic recycling is the best example. Now more than ever the solution seems not to be the substitution of plastic, but a systems-level approach on a global scale to improve its recycling.

Let us remain on the concept of “circular economy”. Reaching a “circular economy” means structuring economies on the virtuous closed loop of make – use – recycle in which every product is designed to be used and then disposed leaving no traces, it means being re-used to generate other products and so on.

All good so far but is this really the full picture? I mean if we recall the primary goal of a circular economy, that is to cut CO2 emissions as main cause of global warming, then the carbon footprint contribution of our activities should be the main driver. Instead, some solutions emerging and defined as 100% recyclable produce actually higher CO2 emissions than what they are replacing and can’t therefore be sustainable for the future.

Looking in particular at the single use packaging sector, plastic packaging is the most attacked material and, as a consequence, we see a shift to other raw materials that are not automatically more Carbon footprint friendly than plastics. This is often an emotional answer to social media attacks that could be even more harmful from a system point of view. As an example, replacing a PET bottle with a glass one, is not the solution. Glass is defined as 100% recyclable and therefore eco-friendly. A consumer might not realize, however that to produce and recycle that glass bottle a huge quantity of energy will be required (melting process goes to temperatures as high as 1500 °C). On top, logistics costs related to collection, transportation to the recycling site and then all the way back to the market again will have much more negative impact compared with a bottle made of PET.

What if we try to let consumers learn what’s behind a packaging and why plastics in packaging have become so successful worldwide. The current health emergency is showing one of their unparallel advantages offered to consumers: safety. But plastic packaging does offer much more: light weight, a PET bottle is lighter than any other packaging and therefore consumers can practically carry their on-the-go snacks and drinks while commuting to job; moreover it hardly breaks and its logistic is agile and safe all over the world; lastly plastics are highly recyclable (and recycled already) to enter the packaging value chain again or to be used for a number of other applications, not of lower value (textiles as an example).

Coming now to the Carbon Footprint contribution, plastic packaging helps reduce CO2 emissions, especially when it involves recycling. A recent report of Plastics Europe shows that an increase in the recycling rate of 5mt of plastic packaging would make CO2 emissions falling by 7mt, corresponding to 2,4 million cars less on streets. A PET bottle made of 50% r-PET has a lower environmental impact than a glass bottle (be it single use and reusable) or a tin can. The single use glass bottle is the least environmental unit, even behind aluminium tin which is almost always the runner-up to plastic packaging.

Having said that, there are ways to make a plastic packaging even more sustainable. One way can be choosing additives and colours that add performance and aesthetics while having negligible impact on its recyclability.

This is at the basis of the REFIT concept. REPI as a global colour and additive solutions supplier to the packaging industry has recently launched its REFIT vision, that adds a “R” to the three commonly accompanying circular economy statement: reducing, reusing, recycling …REFITting.

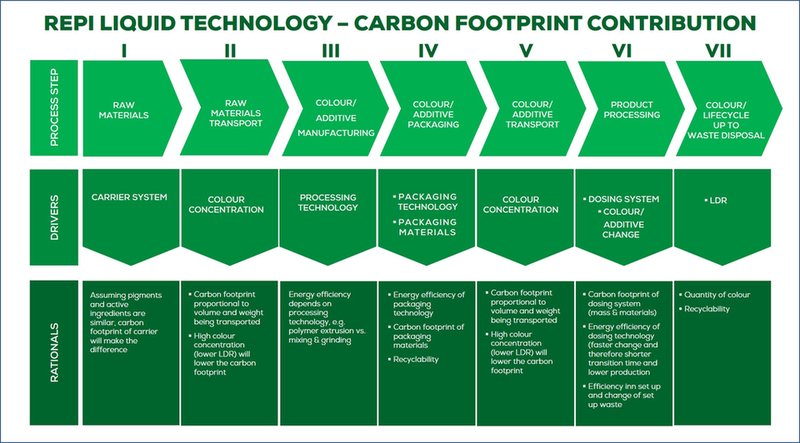

REFIT means having an all-round approach to Carbon Footprint contribution. Protagonist is the liquid colour and additive technology that can be defined as a low Carbon footprint technology.

This can be proven in each step of the liquid lifecycle, as shown in the below flowchart.

The pay off between food, safety and low carbon emphasises the need for innovation.

Just a small selection of the more than 20 resin types moldable by ASB's one-step ISBM machinesJust a small selection of the more than 20 resin types moldable by ASB's one-step ISBM machines

The main reasons behind can be summarized as follows:

- Process - the manufacturing process of a liquid colour/additive is energy efficient since no high temperatures are needed to blend carriers (that are already liquid) with pigments or dyes. Regardless from the specific production cycle, all processes happen at room temperature.

- Logistics – the high concentration of liquids leads to less space needed for transport and therefore significant CO2 saving

- Stockage of liquids at the customer’s site is highly space efficient

Now, coming to products, REFIT comprises additives and colours that are dedicated to plastic recycling and offer a broad-spectrum support in the form of aesthetics enhancers and mechanical boosters: Anti Yellow (AY) additives and IV-Enhancers.

The colour of r-PET varies a lot from supplier to supplier (and even from one batch to the other) and depending on the ratio of recycled PET used, the result can be anything from grey or pale yellow, to blue or greenish. The more recycled content the bottle has, the darker the end colour will appear. The AY range comprises different liquid additives able to balance the appearance of variations in material and to regain brightness, correct a greenish or greyish tone.

Mechanical challenges, instead include a drop of the Intrinsic Viscosity (IV) when using recycled PET. This happens because PET, after several production cycles, due to degradation, shows a reduction in the molecular weight: its chains are shorter, and the final product is mechanically weaker. REPI’s IV Enhancer combine shorter molecular chain to longer ones, thus increasing the IV of the material.

Besides additives, colours can also come to the rescue. When a very dark r-PET is used and an Anti-Yellow additive is not enough, corrections through colour may be crucial. REPI’s Fumé colour range is made of shades like ambers, light blues, greens or greys, that are used at very low dosages (as low as 0,05%) so not to impact the recycling stream.

The entire value chain of plastic packaging has be

en working hard and constantly for many years on making plastic recyclable and recycled.

Now more than ever, I like to think that the world after the pandemic will be wiser and more collaborative on a global scale. I want to believe that we are learning that blaming one solution against the other is not the right choice because, after all, each challenge has different facets and none of them can be overshadowed.

Let's RE-focus instead on what “delivering the circular economy” means, without forgetting the carbon footprint impact of our choices. This is the only way to get to structured solutions, that will be effective and positive in the long run. Let’s be careful not to look at circularity with too narrow lens.