Company Insight

Sponsored by Now Plastics

Building Resilience in the Face of Supply Chain Crisis

Polyethylene Terephthalate (PET) made its first impact on the container molding industry via carbonated soft drinks during the late 1970’s just as Japan’s Nissei ASB Machine Co., Ltd. was founded. In those early days only three machine manufacturers existed globally that produced equipment capable of stretch-blow molding this new material.

The inevitability of disruption

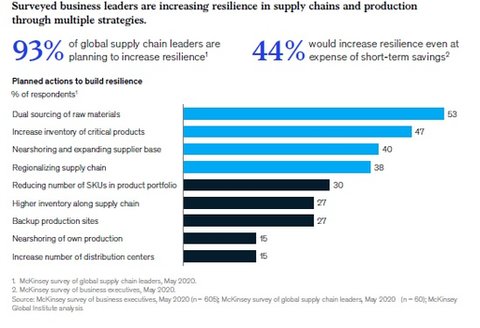

COVID-19 has thrown the world into turmoil. Yet, the disruption to global production that has followed in its wake is far from a ‘one-off’. According to a recent report by the McKinsey Global Institute, disruptions lasting a month or more occur every 3.7 years, with shorter periods of disruption occurring even more frequently.

The cause - natural disasters, escalating global trade disputes, tariff increases, or geopolitical tensions – may be unavoidable. The results - factory closures, compromised supply chains, and massive economic harm - can be devastating. But, with an understanding that some level of disruption is always a possibility, businesses can - and must - protect themselves.

Preparation - The Key to Success

The McKinsey report sets out a number of ways to build supply chain resilience, including improving risk management, increasing redundancy in supplier and transportation networks, holding more inventory, and spreading production capacities across multiple sites. What all these measures have in common is that they require forward planning – or a supply partner like Now Plastics!

Exhibit from “Risk, resilience, and rebalancing in global value chains”, August 2020, McKinsey Global Institute, www.mckinsey.com. Copyright (c) 2020 McKinsey & Company. All rights reserved. Reprinted by permission.

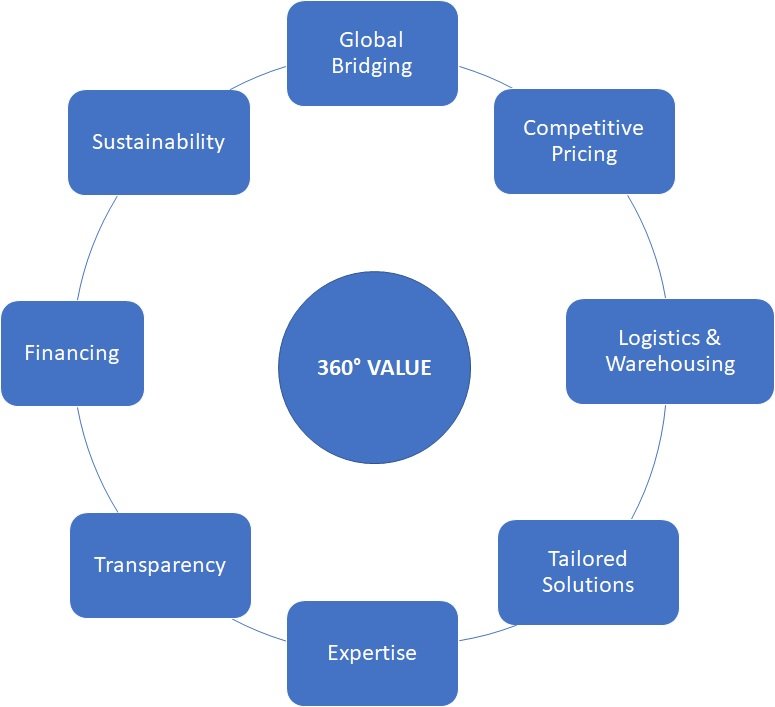

NOW Plastic, a Global Supply Chain Solutions Organization

Now Plastics provides much more than world class plastic films, aluminum foil and other packaging products. Now Plastics offers its converter customers a full range of supply chain services - logistics, financing, product warranties, procurement risk mitigation and a great deal of experience from over four decades of servicing the flexible packaging industry.

Now Plastics goal is to assure customers a seamless import experience. The company serves the flexible packaging, label and industrial converting industries in North America, Central and South America, the United Kingdom, Europe and North Africa. Its products are sourced from over 60 manufacturers around the globe.

Supplier networks, are a major point of vulnerability for any company, but the risk can be mitigated by building active relationships with a diverse, global supplier network, covering not only manufacturing but also transportation and logistics. In the event of a supply breakdown in one region, a business with a well-structured network can call on suppliers in other locations that remain up and running. Similarly, creating capacity to hold extensive backup inventory (’safety stock’) can help ensure that there is always stock instantly available, both in times of supply disruption, and to meet sudden spikes in demand. This is exactly where Now Plastics’ global network comes into play.

Now Plastics – a proven, pro-active approach

With over 40 years’ experience in supplying various plastic films and substrates, aluminum foil and other products to flexible packaging converters around the world, Now Plastics has weathered a wide variety of storms – literal and metaphorical. Anticipating world events, we make sure we are positioned to offer our customers suitable alternatives to prevent any supply chain disruptions, as many large and medium-size converters can testify. And we continue to do so throughout the current COVID-19 pandemic.

At the core of our well-planned, diverse and strategically-structured approach lies a network of 60 hand-picked, all vetted, suppliers from all over the world, ensuring that the majority of our products is backed by at least three suppliers, from three different countries. We also offer unique flexibility in financing and stock holding programs, and deliver first-class logistics management of every single order, every step of the way. Delivering the highest value in terms of quality, price and service, makes Now Plastics the perfect partner to help you overcome the challenges of COVID-19, or any other event threatening your plastics supply chain.

PET shortage (global, 2010-2012)

Anticipating a shortage in the supply of PET, we were able to secure enough capacity from across our supply network to ensure zero disruption to our converter customers.

China alu-foil antidumping tariffs (EU – 2016, US - 2018)

As well as advanced preparations to secure non-Chinese supply alternatives in both cases, in 2016 we worked with the EU Commission to create a unique exemption for flexible packaging in Europe.

Background image blablablablablablablabla