Yes: nature and oceans are polluted; almost 800 animal species are affected by marine debris, micro plastics have spread to the world’s most remote areas.

Extreme ecologists are clamouring for plastics to be completely banned.

We in the sector of plastics must contrast arguments based on common sense and on our extensive know-how to ideas with a strong emotional impact. We should not forget that plastics reflect our contemporary frenetic lifestyle: the speed with which we work and move imposes fast-paced tools and plastic food packaging is the perfect example: practical and functional, it allows shopping once a week and offering long shelf-life products.

We in the sector of plastics also know that wherever efficient waste management systems (collection and treatment) are in place the problem is by far of a minor impact and becomes indeed a factor of economic development.

So it happens that across the entire packaging value chain Brand Owners set goals of raising recycling rates, packaging converters share them, the European Commission and the United Nations make them more challenging and finally consumers look more and more for sustainable products.

And it is not over here... as proof of the potential that plastic can still offer once recycled, recycling targets are increasingly focused not just on the quantity but even on the quality of the recycled material.

REPI as a supplier of colourants and additives worldwide plays a crucial role alongside the plastic packaging channel: It provides solutions that make for example the use of 100% R-PET possible, restoring aesthetics as well as mechanical properties (Intrinsic Viscosity above all) of a recycled PET as it was a virgin PET.

Optimize your ground coffee production by choosing the right packaging solution

PET is the preferred material to package food and drinks: it is light, totally transparent and…easily recycled, to produce either the same packaging again, or other useful items, such as fibre, fabric, strap, car parts and other injection-moulded parts.

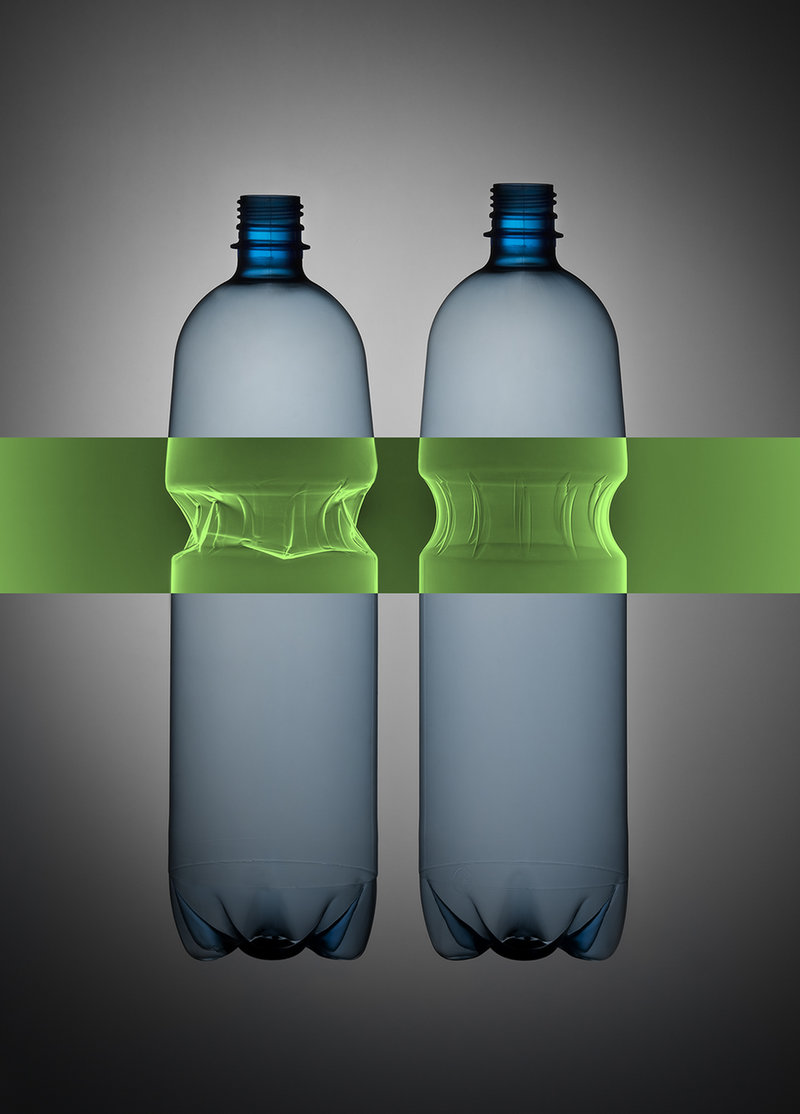

Nonetheless, R-PET can lose some of its exclusive qualities such as strength, connected to its intrinsic viscosity, or its transparency due to the crystallisation of the material. In addition, recycled PET has most of the times a greyish, yellowish or even a greenish tinge. This is merely a visual matter, but affects its attractiveness. A transparent packaging with a yellowish shade is not well taken by the buyer and can become the reason for a lost sale.

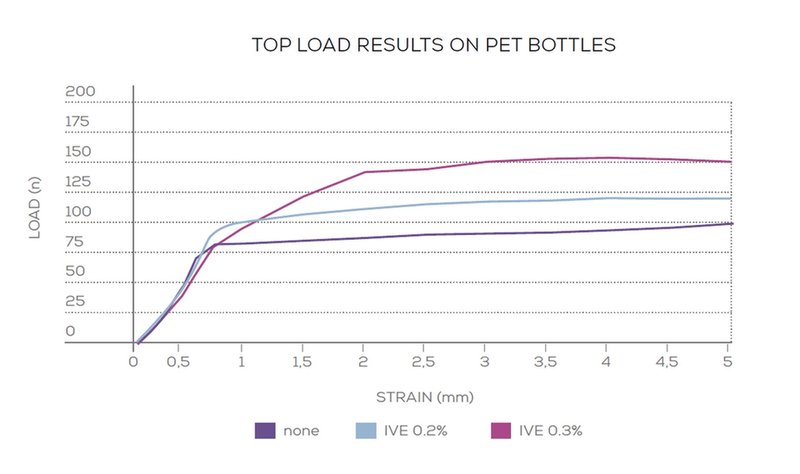

REPI’s IV Enhancer Additives range are able to increase the IV from 0,05 dl/g to over 0,10 dl/g depending on the LDR. Not only, they balance the IV “peak” resulting in more homogeneity of the final mixed resins.

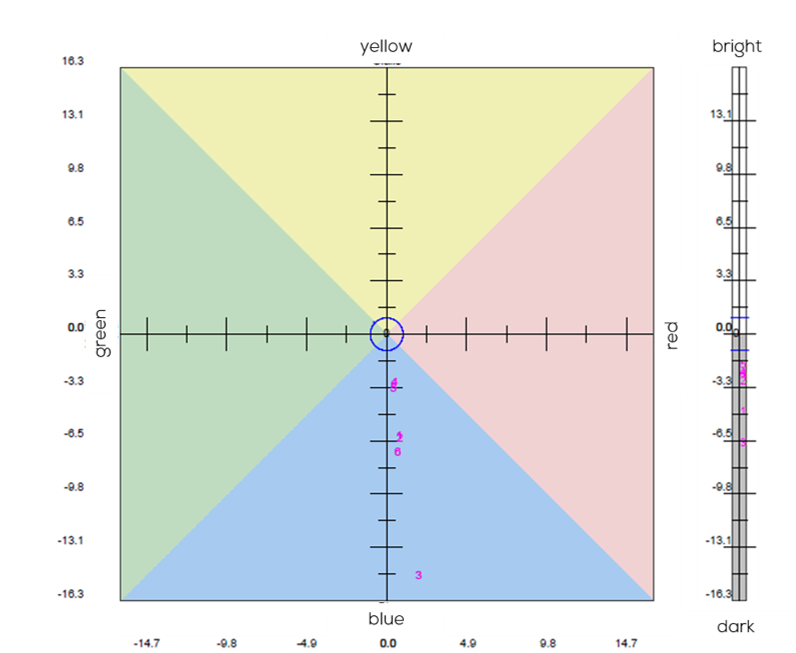

As mentioned, aesthetics is crucial for a R-PET packaging. To help in this situation, REPI provides a range of additives that correct the off-shade of the recycled material bringing it back as it was freshly produced: the Anti Yellow Additives range comprises different grades able to correct, balance and stabilise the L - a or b CieLab values on a case by case basis. Yes, because as we know the incoming material can vary a lot from batch to batch.

So it happens that yellowish PET can be corrected by Anti Yellow REMAP 00015, that acts on the “b” index (yellow-blue axis).

With the same metrics, Anti Yellow REMAP 00201 helps not only to neutralize yellowness (b value), but it also avoids the “L” drop, that is it prevents R-PET to lose brightness and therefore to become greyish (brightness-darkness axis). Anti Yellow REMAP 00153 is used instead with greenish incoming material (green-red axis).

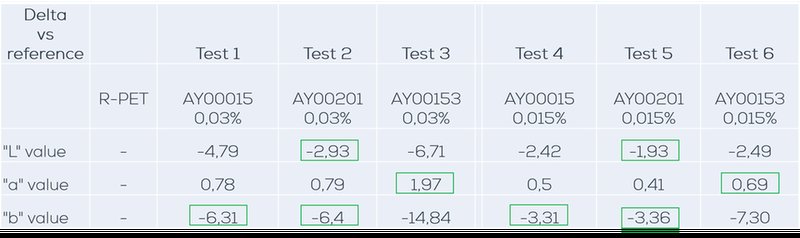

The table below shows the behaviour of Anti Yellow Additives, at two different LDR versus R-PET reference. The best results achieved by each code are marked in green.

These liquid additives can be added at different stages of the process: during R-PET production or directly into the screw of the injection moulding or extrusion lines. Especially this second option gives the user extreme flexibility, who could evaluate and choose the best additive according to the specific incoming material batches. Results are granted even with very limited dosages, which set normally between 0,005% and 0,01%.

Such Analysis is being performed by REPI Light Meter: a preform colour consistency control instrument, which offers a scientific alternative to visual control for all coloured and transparent preforms. The instrument is equipped with a light source and several sensors able to catch, at different levels of sensitivity, light passing through the preform wall to the test cell. The sensor system gives electrical signals proportional to the amount of light passing through the preform wall. Light Meter is often used in production to check preforms before they move to the blowing stage.

International goals, new sorting and recycling processes, the formulation of smart additives…all developments and initiatives are driven by the same vision of embracing a circular economy mindset, a plan of actions that covers the entire lifecycle, from production to waste management and the market for post-consumer plastics.

In this context, I can say to feel very confident that the sustainability of plastics will overcome the irrationality of prejudices and emotional impact.

The path to reach the challenging goals is long and the room for improvement wide, but solutions exist already, we just need to adopt them in a systematic way.

Contact Information

Lucia Buffoni - Marketing Manager REPI S.p.A.

Web: www.repi.com