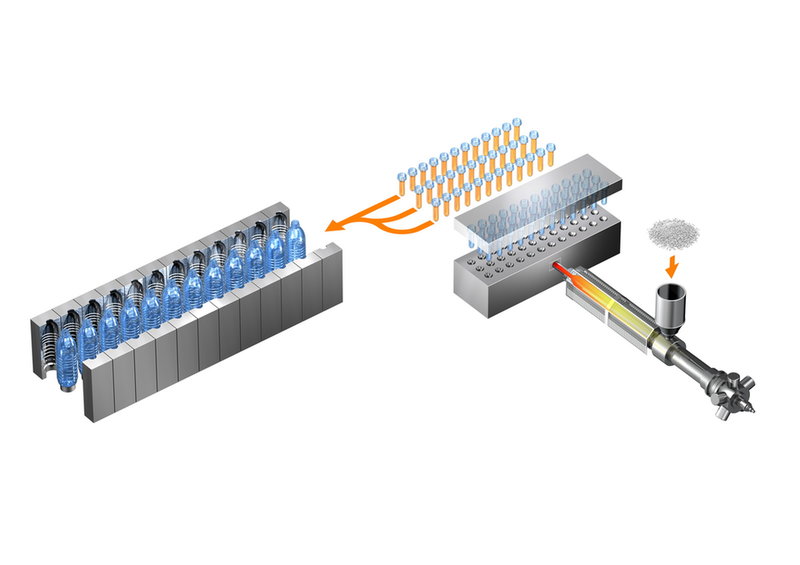

Polyethylene Terephthalate plastic resin, or PET has been in use since after WWII, generally as fibers where it is more commonly known as polyester. The process of injection stretch-blow molding PET into extremely strong, lightweight and clear bottles was developed later during the 1970’s by DuPont in the USA.

Meanwhile in Japan’s Nagano Prefecture, molding machines for this new bottle making process were being developed by the newly formed Nissei ASB Machine Co., Ltd. which was formally founded in November of 1978. The business focused on the manufacture of molding machines as well as injection and blow molds that are required to make a container.

Initially, the main global market was for carbonated soft drinks but due to the many technical advantages of PET over conventional container molding materials it was not long before a wide range of food, beverages, cosmetics, household and personal care products began switching over to the new material. A quick glance at any supermarket shelf today will show that PET is easily the dominant container molding material for a huge range of products in bottles and jars. Simple commodity products such as soft drinks, water and edible oil are often molded in very high volumes by a process known as 2-step molding. Nissei ASB on the other hand, specializes in the 1-step molding method that offers far greater versatility for diverse or niche designs as well as highly technical and non-food containers.

As PET container demand grew, many machine makers arrived on the scene – some became successful, but many have failed or have been absorbed, meanwhile Nissei ASB has continued to thrive and grow as an independent company, maintaining its place as global leader in the 1-step market. Even when including all PET molding machine from the vibrant 2-step sector of the market, Nissei ASB’s turnover currently accounts for around 15% of global sales in all PET container production.

Image of ASB's 1.5-step concept

ASB’s headquarters and main factory are still in Nagano Prefecture, but over the years the company has grown significantly. To combat rising manufacturing costs, in 1997 a major manufacturing unit was set up near Mumbai in India that now produces most of ASB’s injection and blow molds as well as machine parts and some locally developed machine models. Now in November 2018, the company is celebrating its 40th anniversary with further expansion consisting of two new factories, one near its HQ in Nagano and a 3rd phase development at its Mumbai plant with the effect of doubling its global manufacturing floorspace.

In addition, the company has developed a worldwide network of 16 subsidiaries with a new technical center having been added at its Atlanta, USA sales office in 2017. A further list of over 40 sales agents completes global coverage and ensures that ASB customers in over 140 countries are never far from sales or technical support.

Since the company produced its first injection stretch blow molding machine over 40 years ago, the market has constantly put greater technical demands on container molding technology and at each step, Nissei ASB has responded by continually expanding the range and capabilities of its products to fulfill the needs of future market development.

Despite focusing entirely on machine and mold manufacture, today the company produces five distinct product lines covering a wide range of technologies to cater to various needs whether it be technical molding, high productivity, versatility of molding resin or highly specialized niche products.

Photo of photo-realistic flexible packaging.

Its original 4-station 1-step injection stretch blow molding machines known simply as the ASB Series still account for the majority of the company’s turnover due to the extreme versatility of the system not only for PET containers but a wide range of alternative materials having specialized properties. The other four product lines known as the PF Series, PM Series, CM Series and HSB Series are dedicated to PET containers and cater to a combination of high productivity for standard containers or heat resistant containers for hot filled or pasteurized products.

Throughout its 40 years, ASB has built its reputation on diversity and flexibility - a quick look at the history of the company reveals many “world-firsts” and a long list of patents that tells a tale of long term commitment to research & development both as an industry leader, and as a company that reacts to the needs of its customers.

Today, both Nissei ASB and PET remain firmly at the forefront of the container injection stretch blow molding industry. As for the future, no-one can predict which direction the industry will take, but there is one certainty - wherever it goes, Nissei ASB will be right there at the front continually innovating for tomorrow.

Contact Information

NISSEI ASB MACHINE CO., LTD.

4386-3 Koo, Komoro-shi,

Nagano-ken, Japan 384-8585

Tel: +81 (0)267 23 1565

Fax: +81 (0)267 23 1564

Website: www.nisseiasb.co.jp

Email: sales@nisseiasb.co.jp