‘’We continue to operate with a relentless focus on safety, innovation and efficiency – both in our manufacturing processes and our use of resources.

That discipline has enabled us to reduce our overall energy consumption and greenhouse gas emissions, even as demand for metal packaging has continued to increase and we have grown our global footprint.’’

– TIMOTHY J. DONAHUE

President and Chief Executive Officer

We are CROWN Brand-Building Packaging™, and we are creating an infinitely brighter future!

We are CROWN Brand-Building Packaging™, and we are creating an infinitely brighter future!

Building on a tradition of innovation, quality and cost control, we reach ever greater heights as we diversified packaging solutions and services to meet our customers’ needs. We are the only company with the breadth and depth of product lines in metal, the most sustainable material available, enabling our customers worldwide to build their brands.

Read more >

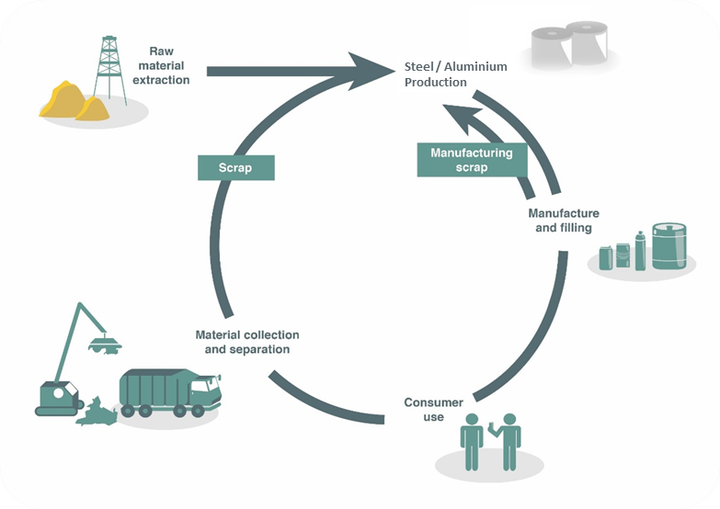

When a metal product reaches the end of its useful life, the material is never lost.

Metal is a permanent material.

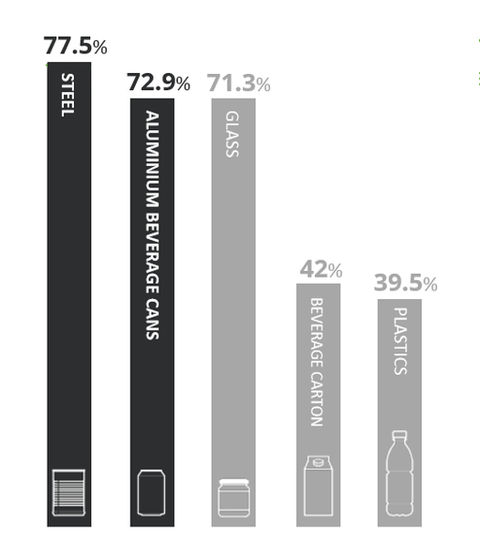

The Circular Economy Package (CEP) establishes an ambitious and credible long-term path for waste management and recycling. It envisages higher recycling targets for all packaging materials, notably 75% for ferrous and non-ferrous metals by 2025.

Source: European Aluminium and APEAL

70%to 95% of energy is saved when using recycled metal

Metal is 100% Recyclable

Source: European Aluminium, APEAL, Metal Packaging Europe

Read about Diagram >

5.3%

As of December 31, 2016, energy consumption has been reduced by per billion standard units.

Decreased direct GHG emissions by 10% and indirect GHG emissions by 8%

Lower VOC emissions by 17% and NOx emissions by 18%

Reduced aluminum usage by 4%

Decreased landfill waste by 49%

Had zero work-related fatalities.

Decreased direct GHG emissions by 10% and indirect GHG emissions by 8%

Lowered VOC emissions by 17% and NOx emissions by 18%

Reduced aluminum usage by 4%

Decreased landfill waste by 49%

Had zero work-related fatalities.

When a metal product reaches the end of its useful life, the material is never lost.

Metal is a permanent material.

The Circular Economy Package (CEP) establishes an ambitious and credible long-term path for waste management and recycling. It envisages higher recycling targets for all packaging materials, notably 75% for ferrous and non-ferrous metals by 2025.

Source: European Aluminium and APEAL

70% to 95%of energy is saved when using recycled metal

Metal is 100% Recyclable

Today, 74.7% of metal packaging is recycled in Europe, making it the most recycled packaging.

CO2 Emissions from a standard steel can today are30% lower than 15 years ago

Building on a tradition of innovation, quality and cost control, we reach ever greater heights as we diversified packaging solutions and services to meet our customers’ needs. We are the only company with the breadth and depth of product lines in metal, the most sustainable material available, enabling our customers worldwide to build their brands.