Insight

Good plastics v alternative packaging materials

Inside Packaging investigates why packaging experts and members of the public voted for alternative materials over and above good plastics in a recent survey.

The differences between plastics

Plastic packaging comes in a range of forms from PET (polyethylene terephthalate) and HDPE (high-density polyethylene) to PVC (polyvinyl chloride) and PS (polystyrene). Each type provides its own benefits but not all have recyclable properties.

Looming global environmental targets have encouraged innovation within the packaging space, leading many businesses to opt for recyclable plastic packaging as an alternative sustainable solution. This has seen the introduction of many pulp-based and food-based packaging alternatives.

One of the challenges facing the sector, however, is many of the alternative packaging materials on offer do not suit the requirements of the product being housed within. As a result, some businesses are leaning towards ‘good’ plastics as opposed to non-plastic sustainable materials.

Recyclable plastics (PET and HDPE) and bio-based plastics (Bio-PET or Bio-PE) are often viewed as ‘good’ plastics due to their ability to be recycled and contribute towards a circular economy.

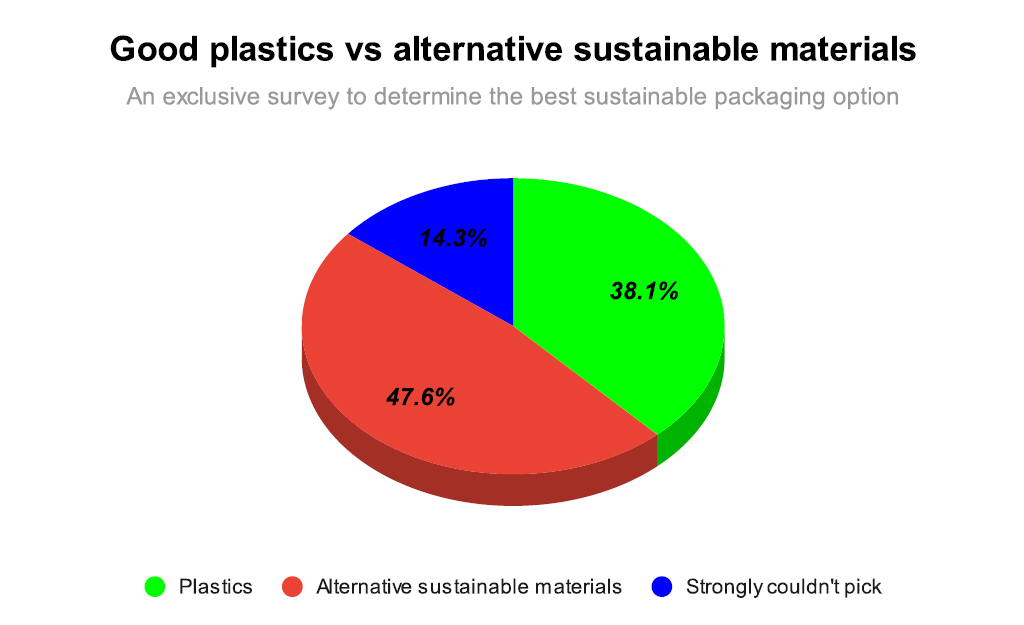

The survey conducted by Inside Packaging, which included both packaging experts at the Packaging Innovations and Empack packaging exhibition and members of the public asked: What is the best sustainable packaging material between ‘good’ plastics and alternative packaging materials?

The survey found almost half of the respondents (48%) view alternative materials as the best option compared to the 38% who opted for good plastics. Many of those surveyed told Inside Packaging moving away from plastics is the best option if it has a positive impact on the environment.

A high percentage of those that chose plastics said it has a key role to play in packaging due to its flexibility, cost and the fact there are global infrastructures in place to recycle polymers and keep them within a circular economy.

A place for plastics

Plastic pollution is widely regarded as a global health crisis and most consumers see plastics as bad, but this isn’t always the case. There is a range of recyclable plastics available that fit into a circular model and some would argue plastics within packaging are necessary to bring many products to market.

Polymer producer Liz Rettweger who is the commercial director for Ineos Olefins & Polymers Europe told Inside Packaging there is a place for plastics within packaging.

“There’s a place for plastics just as there is a place for aseptic (sterilised) packaging.”

She explained there are situations where it will be the best fit for a product, and added: “It depends on the product you’re protecting, the customer base that you’re supplying, how you’re supplying it and where the customer is.”

This could explain why 14% of those surveyed by Inside Packaging were undecided about the best sustainable solution and believed both plastics and alternative materials have a place within packaging.

Rettweger continued: “What’s important in all kinds of packaging, is that we work on reducing its environmental impact. No matter what the package is, you must look at the carbon footprint. Look at how it’s made, how it can become more circular and even how it’s distributed to the customer.”

According to the British Plastics Federation (BPF), plastics offer unrivalled benefits such as being lightweight and offering barrier protection, whilst significantly reducing waste and saving energy. In fact, the organisation stated food waste in the UK is only 2% compared to 40-50% in developing parts of the world, due to the role that plastics play in keeping food fresh. For example, a cucumber loses moisture quickly and would be unsaleable within three days were it not protected by 1.5 grams of plastic.

A recent report by GlobalData, Inside Packaging’s parent company titled ‘ESG in food service’ reported that an increase in negative perceptions around plastics among consumers will most likely accelerate a shift towards recyclable plastics.

“While recycling is a step in the right direction, it is not the ultimate solution to sustainability as many recyclable plastics are simply not recycled and energy is still required to turn used products into new ones. As plastics remain in circulation, they are always at risk of ending up in landfills or oceans at the end of their life,” the report explained.

Removing ‘bad’ plastics from packaging and creating a sustainable future requires innovation. The practice of developing alternative sustainable packaging materials has grown over the past few years with more packaging companies bringing eco-friendly solutions to market.

For example, British chemical company Ineos recently partnered with Chinese packaging company Greatview Aseptic to develop its first sustainable aseptic packaging option, using fully bio-based products, plastic and card.

Speaking about the collaboration Ineos’ Rettweger explained: “Polymer adds a layer of protection to the food that’s packaged inside the carton packaging. By producing it in this way with 100% renewable power and producing it from bio-attributed feedstocks, it is a very sustainable solution for packaging food for the consumer.”

Plastic alternatives

The creation of packaging from paper and pulp-based materials has become an increasingly popular idea with companies such as British packaging firm Frugalpac and Swedish pulp and paper manufacturer BillerudKorsnäs who implemented a sack paper to replace plastic film barriers. Plastic was previously seen as a necessity for keeping products fresh whilst packaged. Frugalpac, who is said to have created the world’s first commercially available paper bottle for wines, spirits and oil, recently sold the first Frugalpac Bottle Assembly Machine (FBAM-1) to Canadian packaging firm KinsBrae Packaging with the aim of pushing sustainability further.

“We looked at what we could do with some of our technology and felt we could make a lower carbon product that would be of interest to consumers as well as our customers,” explained Frugalpac’s chief executive Malcolm Waugh at the time.

He said the Frugalpac bottle is predominately made from paper, but plastics are still required to make a paper bottle that doesn’t leak.

“The package is 16% plastic film. That 16% plastic allows us to use 84% recycled content in the bottle by weight and that’s what drives the carbon down. The combination of both of those materials gives us a very sustainable package.”

Waugh added Frugalpac doesn’t contaminate its packaging by laminating the materials together. Instead, they are mechanically fitted to make the separation process easy and create a 100% recyclable package. The cross-contamination of materials is an industry-wide problem and according to Waugh, the recovery of film or flexible packaging is less than 4% in the UK.

Global drinks brand Carlsberg created a bio-based fibre bottle and launched trials across eight European markets. The bottle is a move away from glass and Carlsberg decided against using plastics, opting for a bio-based and degradable material. The bottles are made from wood fibres and feature a plant-based polyethylenefuranoate (PEF) inner lining.

“PEF is a revolutionary alternative polymer – not only is it made entirely from renewable raw materials, but it can retain carbon dioxide better than conventional PET plastic, so both the environment and our beer can benefit,” said Simon Boas Hoffmeyer, group sustainability director at Carlsberg. “PEF was chosen for the inner barrier due to its sustainability credentials such as being bio-based, degradable and recyclable, as well as its technical properties which met our strict quality standards.”

Degradable packaging is growing in popularity and British biotech start-up Shellworks has created a vegan, compostable alternative to plastics with a new material called Vivomer. It is made from bacterially derived components that are grown via a fermentation process. Compostable packaging is a wholly sustainable option; however, some believe it is only viable if there is a circular model in place to avoid it ending up in landfill.

Shellworks co-founder Amir Afshar pointed out if the recycling stream existed for the materials everything would be recycled. He said the problem with a lot of materials made from plastics however is that the recycling streams don’t exist. Afshar highlighted this makes it an interesting debate and says when most people think about recycling, they believe that putting items in a household recycling bin means the items will be recycled. This is not the case, he argued as in reality half of that recycling waste ends up in landfill.

“If you look at the statistics, roughly 20% of people have access to compost, maybe a little bit higher depending on location. But only 9% of materials ultimately get recycled, so even at that level, composable materials are about twice as effective,” explained Afshar.

What’s the solution?

If waste is not recycled and only ends up in landfill, an alternative material with higher composable and compostable properties could be viewed as being better for the environment than sustainable plastic packaging.

Packaging experts believe consumers need options for the industry to prosper. Increased public awareness around packaging material properties and working circular models are important factors to be considered. The experts point out that not all plastics are ‘bad’ and polymer materials such as PEF and RPET are good examples of how plastics can be beneficial as long as circular models are effectively in place.