Packaging suppliers are having to manage new processes and increasing demands from customers, which can often be a challenge. But, meeting exacting and specific customer needs is central to what supply chain companies must do. In our increasingly competitive world, customers expect brilliant service at every turn and this means focusing on quality and consistency. In the past, the packaging industry has suffered with a poor reputation when it comes to customer service, due mostly to DPPM (defect parts per million) and OTIF (on time in full delivery) figures being shown to be well below those of other industries. This reputation has not helped packaging manufacturers.

Nevertheless, technology is now changing everything. We have the capability to design boxes with fewer imperfections, shorter print runs and to a more accurate specification. This increased capability does mean our customers are asking for more and expecting higher standards. So how should we, as packaging suppliers, respond to this increasing pressure?

Improving the supply chain anD Exceeding customer expectations

Embrace the change. Every time we make an improvement, the expectations of our customers increase. This should be viewed as a positive. These increased expectations keep the supply chain on its toes, hungrEmbrace the change. Every time we make an improvement, the expectations of our customers increase. This should be viewed as a positive. These increased expectations keep the supply chain on its toes, hungry for improvement and means we constantly challenge ourselves to be better at what we do every single day. It means there is no scope for resting on our laurels – we have to continually innovate and improve our offering.

In addition, it is essential to focus on quality of product (ensuring it is fit for purpose and looks exactly like it should, every time), as well as providing service levels above and beyond the industry average. One example of this for us would be the development of real-time, quality testing software which is unique within the industry and gives our customers a level of reliability, consistency and reassurance that they will not be able to find from any other supplier.y for improvement and means we constantly challenge ourselves to be better at what we do every single day. It means there is no scope for resting on our laurels – we have to continually innovate and improve our offering.

Technology is now changing everything

The ultimate goal is to become a partner to your customer, an extension of their own business and a part of their team. You need to be seen as the “go to” company. If a company faces a challenge in its business, you want its immediate response to be to turn to you as its supply chain partner and source of inspiration, creativity and support.

This is achieved by building a reputation that demonstrates you are the type of business that listens and understands their market and daily challenges, and is always keen to offer a solution to the problem.

Customers want solutions that reduce waste

One size does not fit all when it comes to packaging. To truly meet customer needs, a packaging strategist needs to offer every customer a unique manufacturing solution and understand what they most require. Today customers want solutions that reduce waste, reduce carbon footprints, reduce costs (to increase profits), manage risks and increase sales but they may have other hopes too. It is crucial to really interrogate the brief and get under the skin of your customers to really understand what their priorities are, it’s this insight that will really make you stand out from the competition.

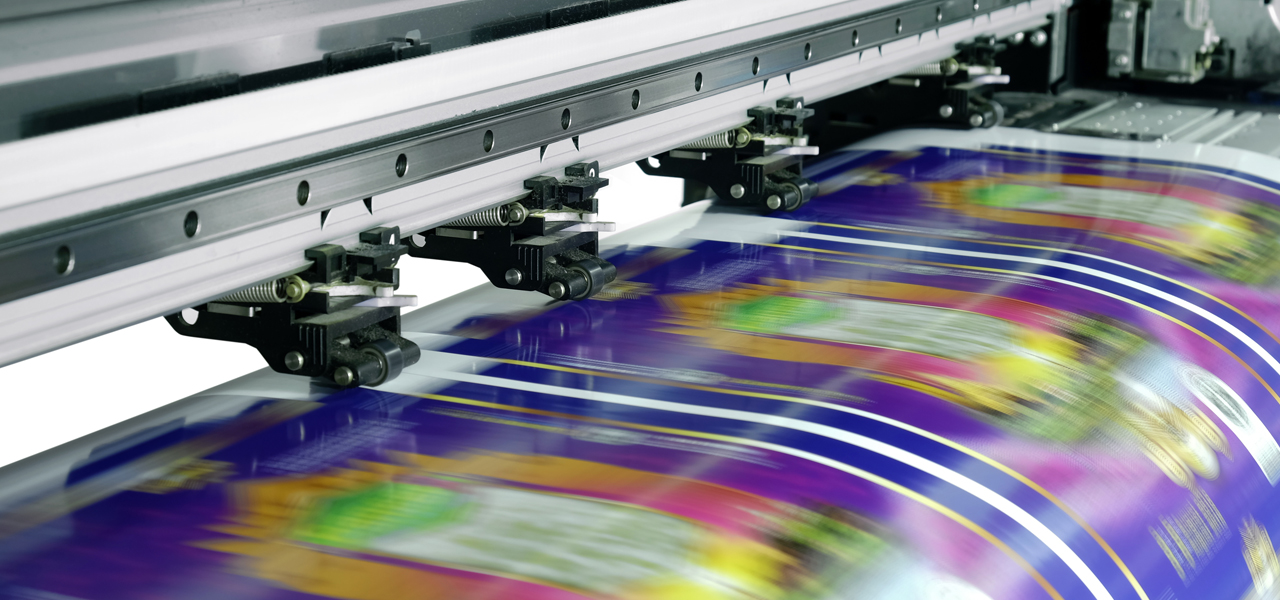

Digital printing enables personalisation and customisation

Another key milestone over the last ten years that has enabled packaging companies to increasingly meet the needs of customers, is the advancement of digital printing. This technology enables smaller print runs and increased amounts of personalisation or customisation.

For example, it is now straightforward to over-print a customer’s logos on to your packaging as well as provide more consistent levels of colour matching and high-quality printing of images. Digital printing can also be used to print on previously under-utilised areas of packaging such as the insides of boxes, as well as anti-counterfeiting techniques and sequential bar codes.

With benefits such as very low minimum order quantities, reduced origination cost and quicker speed to market, digital printing will no doubt become even more important for meeting customer needs in the future.

This is gradually driving innovation

The perfect box is no longer a pipe dream. With constantly evolving technology solutions, there will be a point in the future when all suppliers can create a perfect box every time. When we reach that point, the difference between packaging suppliers will come down to expertise, innovation and service. Becoming a partner to your customers is important now, but in ten years’ time it will be critical. Becoming an indispensable extension of their own team is the silver bullet of customer relationship management.