Even More Efficient.

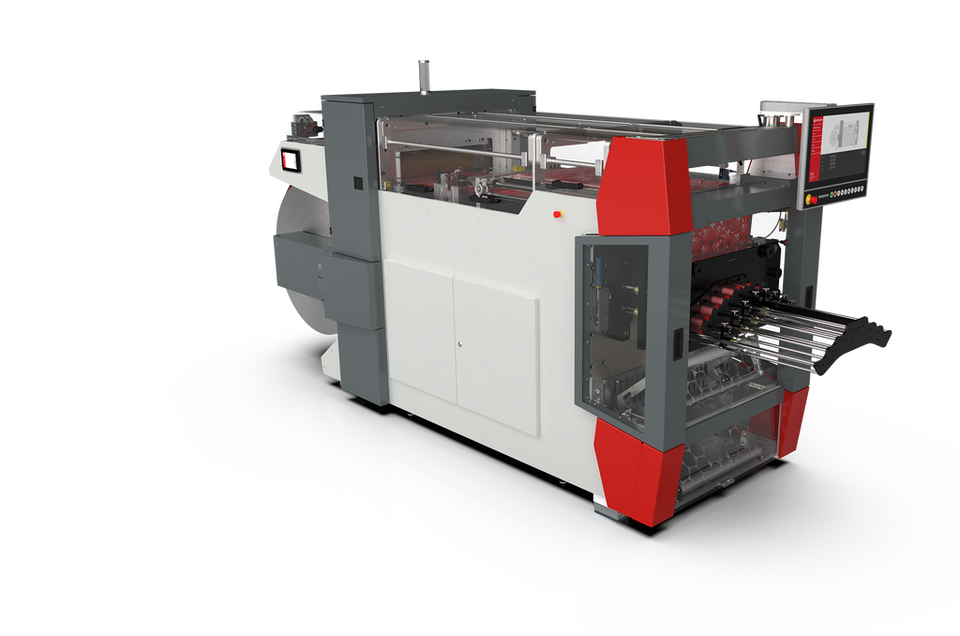

The Revolutionary Swiss Die-Cutter™ B6

Swiss Die-Cutter™ B6

maximum performance and digitalisation

390‘000

output 75.5

500

strokes/min

13

servo drives

610 x 510

tool area

100

m/min

1.9

consumption

Highlights

Output

Ultimate production output. Highest profitability. High-end punching for material widths up to 600 mm and punching speeds up to 500 strokes per minute. Perfectly suited for single-row, double-row and multi-station punching tools.

Drive

Digital punching drive. Highest precision. Freely controlled punching movement, adjustable opening stroke, digitally monitored cutting depth, new active foil guide in the punching tool for optimum dimensional accuracy.

Plug & Play

Intelligent networking. Data-driven service. Reliable monitoring of punching machines, RFID recording of tool and embossing data, dashboard with live data and data analysis, visualization of operating data, OEE and KPI‘s.

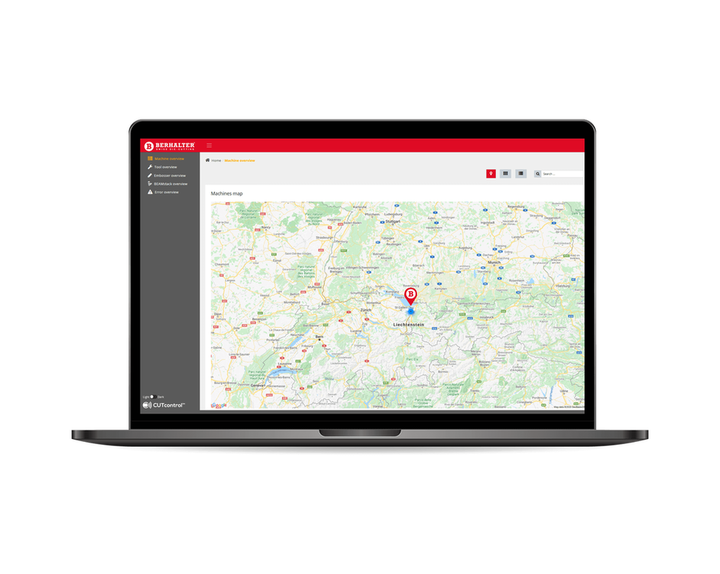

From Things to Value.

Intelligent IIoT Platform. Enabling Customers to Innovate Faster.

CUTcontrol™ Digitalization

Predictive and Preventive Maintenance

Transparency

Makes production process clear

Real Time

Live data of all machines and tools

Dashboard

HTML5 web-based and individualized

Capacity

Increase of machine efficiency

Planing

Condition monitoring through data analysis

BERHALTER Swiss Die-Cutting | CH-9443 Widnau, Switzerland | berhalter.red | die-cutting@berhalter.red

Even More Efficient.

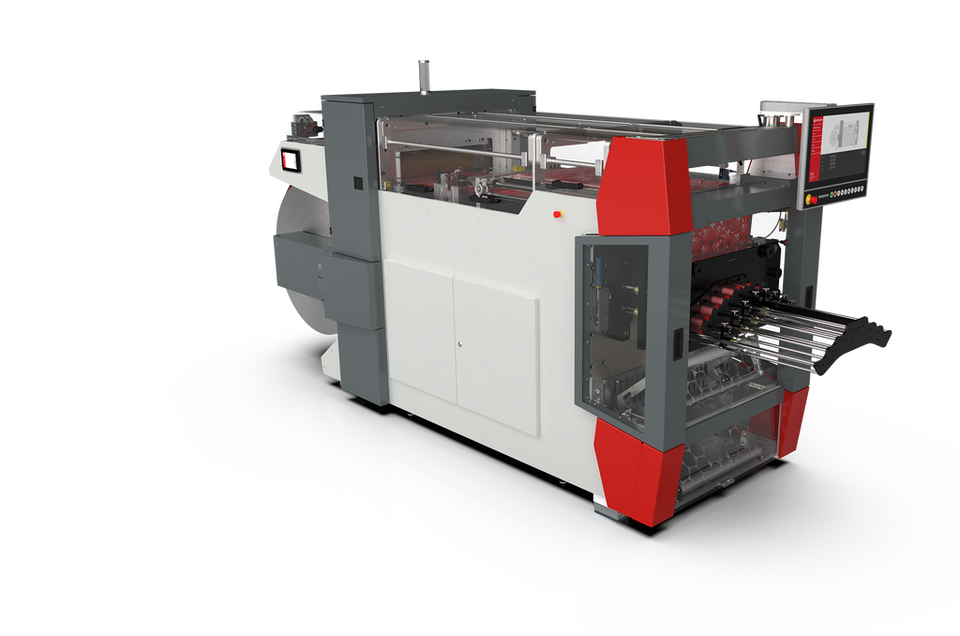

The Revolutionary Swiss Die-Cutter™ B6

Swiss Die-Cutter™ B6

maximum performance and digitalisation

390‘000

output 75.5

500

strokes/min

13

servo drives

610 x 510

tool area

100

m/min

1.9

consumption

Highlights

Output

Ultimate production output. Highest profitability. High-end punching for material widths up to 600 mm and punching speeds up to 500 strokes per minute. Perfectly suited for single-row, double-row and multi-station punching tools.

Drive

Digital punching drive. Highest precision. Freely controlled punching movement, adjustable opening stroke, digitally monitored cutting depth, new active foil guide in the punching tool for optimum dimensional accuracy.

Plug & Play

Intelligent networking. Data-driven service. Reliable monitoring of punching machines, RFID recording of tool and embossing data, dashboard with live data and data analysis, visualization of operating data, OEE and KPI‘s.

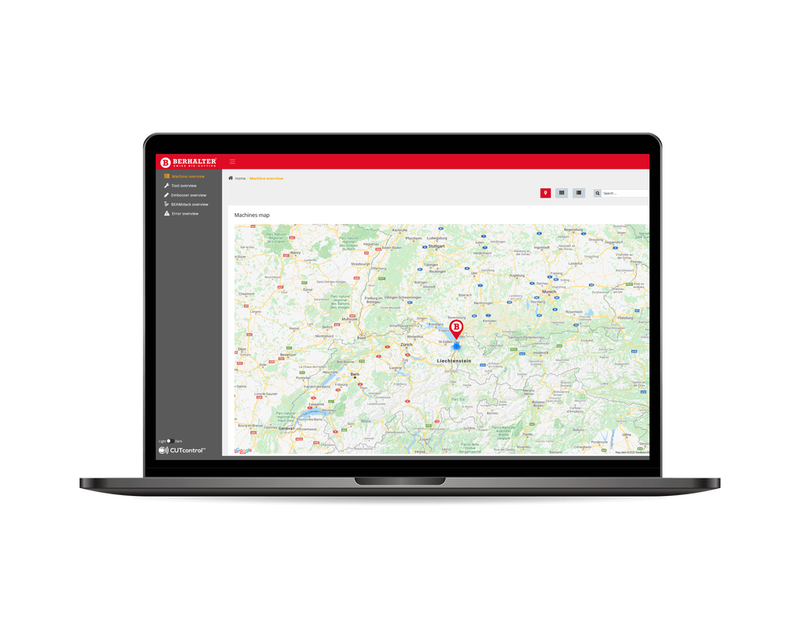

From Things to Value.

Intelligent IIoT Platform. Enabling Customers to Innovate Faster.

CUTcontrol™ Digitalization

Predictive and Preventive Maintenance

Transparency

Makes production process clear

Real Time

Live data of all machines and tools

Dashboard

HTML5 web-based and individualized

Capacity

Increase of machine efficiency

Planing

Condition monitoring through data analysis