Feature

Packaging converting for customised solutions

Converters offer flexible packaging that protects products while aligning with brand identity and sustainability goals. By Mohamed Dabo.

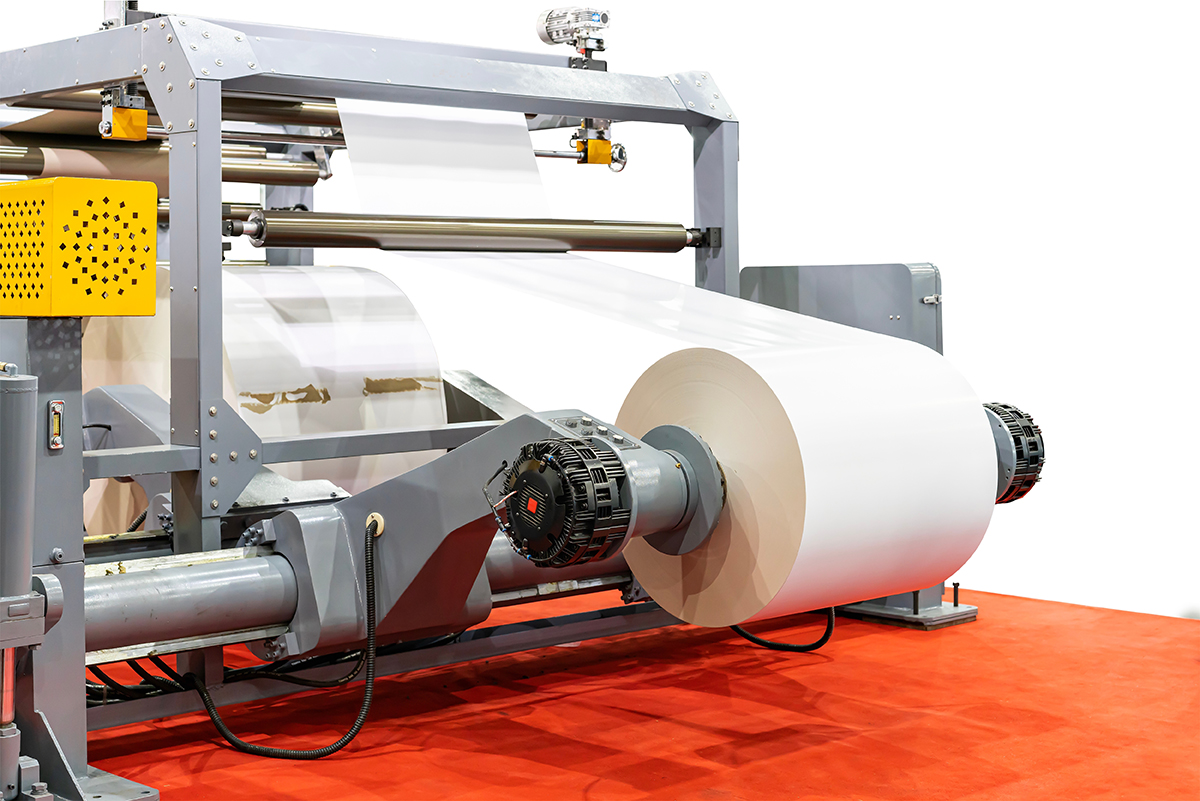

Packaging converters turn raw materials like paper, plastic, and foil into finished packaging solutions. Credit: Surasak_Photo / Shutterstock

In an industry where innovation and efficiency are paramount, packaging converting has become an essential process for businesses seeking tailored solutions.

The ability to transform raw materials into functional, aesthetically pleasing packaging is reshaping industries and enabling companies to meet their unique branding and logistical needs.

Customised packaging offers more than just visual appeal; it serves as a strategic tool in product differentiation, sustainability efforts, and customer satisfaction.

The role of packaging converting

Packaging converting involves transforming raw materials—such as paper, plastic, or foil—into a final product that can be used for packaging.

This process typically includes a variety of techniques, such as printing, laminating, cutting, and assembling. The goal is to create packaging that not only protects products but also aligns with brand identity and enhances the overall customer experience.

A key driver in packaging converting is the growing demand for customisation. Businesses want packaging that reflects their brand’s personality while maintaining functionality and sustainability.

Customised packaging solutions help companies create a distinctive shelf presence, which is critical in today’s competitive marketplace.

Through advancements in technology, converters can now offer a range of specialised options, including unique shapes, high-quality printing, and even interactive elements like QR codes for enhanced consumer engagement.

Flexibility to meet diverse market needs

One of the major advantages of packaging converting is its flexibility. Different industries, from food and beverages to pharmaceuticals and electronics, have distinct packaging requirements.

For instance, food products may need packaging with barrier properties to preserve freshness, while electronic goods require anti-static or shock-resistant materials.

Packaging converting allows for precise adaptation to these needs, ensuring that each product receives the appropriate level of protection. Advancements in digital printing and converting technologies have also enabled faster turnaround times and more cost-effective production.

Smaller businesses, which may have previously been limited to standardised packaging due to budget constraints, can now access customised options without significant cost implications.

This level of flexibility opens up new opportunities for brands to enhance their product offerings and improve their market competitiveness.

Sustainable packaging solutions on the rise

Sustainability continues to be a top priority for consumers and businesses alike, and packaging converting plays a pivotal role in achieving eco-friendly packaging goals.

Many converters are adopting greener materials such as recyclable paper, biodegradable plastics, and compostable films. These materials are engineered to minimise environmental impact without compromising on quality or performance.

In addition to material choices, innovations in converting techniques are reducing waste and energy consumption during production. For example, precision cutting and folding technologies ensure that material use is optimised, leaving minimal waste.

Furthermore, some converters are incorporating post-consumer recycled content into their processes, promoting circularity and supporting companies in meeting their sustainability targets.

By adopting sustainable packaging solutions, companies not only reduce their environmental footprint but also cater to the growing consumer preference for eco-conscious products.

As more businesses make the shift towards greener alternatives, packaging converting will continue to be a crucial enabler of sustainable development within the industry.

The future of customised packaging

The future of packaging converting is likely to see even greater advancements in customisation, particularly with the integration of smart packaging technologies.

Smart packaging, which involves embedding sensors or other interactive elements into packaging, is already being used to improve product safety, extend shelf life, and provide consumers with additional information about the product.

Customisation will remain a key differentiator for businesses looking to enhance their brand appeal and engage consumers on a deeper level.

As the industry evolves, packaging converters will increasingly work hand-in-hand with companies to develop solutions that not only meet practical needs but also resonate with consumers’ values, particularly around sustainability and innovation.

Ultimately, packaging converting is essential for businesses seeking customised, flexible, and sustainable solutions.

As consumer expectations continue to evolve, the ability to offer bespoke packaging that combines function with eco-friendly materials will be a vital competitive advantage.

The versatility of packaging converting ensures it will remain at the forefront of industry trends, offering enduring relevance and continued innovation for years to come.