Valco Melton

Adhesive Dispensing & Quality Assurance Systems

World HQ: +1 513 874 6550

Euro HQ: +34 948 321 585

The EcoStitch All-Electric gluing solution that has revolutionized the packaging industry

Specifically designed for the food & beverage industries, our EcoStitch™ gun is an evolutionary solution for electric hot melt application. Based on a precise adhesive dispensing control, it produces accurate adhesive dot patterns and reduces adhesive usage by up to 75%. Its electric valve can operate at extremely high speeds, reaching up to 15,000 cycles per minute, almost 20 times that of a standard pneumatic valve, and producing dots as small as 1 mm in diameter.

Since this electric technology requires less consumable wear parts, downtime associated with valve failures and repairs are significantly reduced. EcoStitch offers an integrated filter in the manifold and is compatible with industry standard hoses and tanks. It's unique modular design allows for easy change-outs and variable valve configurations.

Valco Melton

Adhesive Dispensing & Quality Assurance Systems

World HQ: +1 513 874 6550

Euro HQ: +34 948 321 585

This is what you get!

EcoStitch guns bring you instant ROI and and significant performance enhancements.

lnstant ROi:

Get a return on your investment in as little as 4 months of use, following install. That's all it takes for this system to pay for itself.

Adhesive Savings:

Valco Melton's EcoStitch applicator helps you reduce your adhesive usage by applying precision dots.

Less Downtime:

Electric gear pumps and electric valves remove almost all seals typically required to run a pneumatic system. This reduces the chance of failure created by too many moving parts instantly.

Easy lntegration:

Valco Melton's modular design and multi-module configurations are easily adapted to existing machines through various mounting options and valve spacing for package requirements.

Valco Melton

Adhesive Dispensing & Quality Assurance Systems

World HQ: +1 513 874 6550

Euro HQ: +34 948 321 585

Kube System

Melt on Demand the way you want it

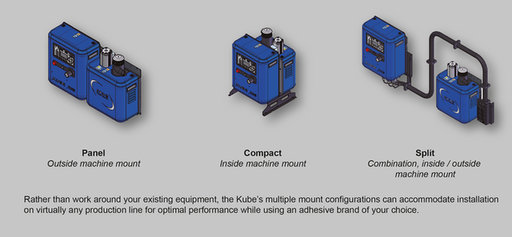

The Kube™ melt on demand system improves production efficiency by promoting adhesive stability and eliminating degradation problems. This melter features an enclosed system with an integrated autofeed option that keeps out dirt and debris, reducing plugged nozzles and maintenance and promoting a safer work environment. An Auto Pressure Pump feature eliminates pressure when machine is open for safer operation. Available in both pneumatic and electric formats, the Kube™ is the only one of its kind to feature three different mount configuration options to fit into any new or existing installation.

Valco Melton

Adhesive Dispensing & Quality Assurance Systems

World HQ: +1 513 874 6550

Euro HQ: +34 948 321 585

PackChek: Assurance system for a perfect sealing

Our automated packaging inspection system PackChek™ takes a thermal and visible image of every package to ensure hot melt glue has been applied properly.

Hot melt sensors have been around for decades, but tight space constraints on packaging machinery makes retrofitting them into existing machines extremely difficult. PackChek™ can be installed at the discharge if your machine, without space constraints.

PackChek has been designed to catch three main types of defects:

- Missing glue beads

- Weak glue beads

- Misaligned glue beads

- Crushed, torn or open flaps

When one bead, or a combination of beads, does not meet a requirement (predetermined tolerance levels configured by the user), outputs can be configured to stop the machine, eject a case, or sound an alarm.

+ Info